How to make license plates---SUNRUI car license plate production stamping line

Car License plates are more than just metal identifiers; they are a universal symbol of vehicle registration and ownership. Their production is a fascinating blend of material science, precision engineering, and stringent security measures. This article explores the materials, dimensions, and manufacturing process behind these everyday items.

What Material is Used for License Plates?

The vast majority of modern license plates around the world are made from aluminum alloy. This material has become the industry standard due to its superior properties compared to the materials used historically.

The Primary Material: Aluminum Alloy

Specifically, license plates are typically made from alloys in the 5000-series (primarily alloy 5052) or 6000-series (like alloy 6061).

These are chosen for an ideal balance of characteristics:

Lightweight: Aluminum is significantly lighter than steel, which reduces the overall weight of the vehicle and lowers shipping costs for bulk plates.

Durable and Corrosion-Resistant: It does not rust like steel. It forms a protective oxide layer that makes it highly resistant to the harsh conditions of road use, including rain, snow, road salt, UV exposure, and impacts from debris.

Malleable: Aluminum is soft enough to be easily rolled into thin sheets and stamped/embossed with characters by high-pressure machinery without cracking or splitting.

Excellent Surface for Coating: It provides a perfectly smooth, clean surface for the adhesive-backed reflective sheeting to bond to, ensuring longevity and preventing peeling.

Other Materials (Past and Present)

While aluminum dominates, other materials are or have been used:

Steel: This was the most common material for many decades, particularly before the 1970s and 80s. While strong, steel is heavy and prone to rust, which led to the industry-wide shift to aluminum.

Plastic/Acrylic: Often used for temporary tags, dealer plates, or promotional novelty plates. They are inexpensive to produce but are not as durable as metal for long-term use.

Carbon Fiber or Stainless Steel: Used for some high-end novelty or custom show plates due to their distinctive aesthetic, though they are not typically legal for standard road use.

Materials for Flat Plates: Some modern plates, especially in Europe, are "flat" or non-embossed. These are typically made from aluminum or plastic blanks that are then digitally printed directly onto the surface.

In summary, if you see a license plate on a car today, it is almost certainly made from a lightweight, corrosion-resistant aluminum alloy, coated with a reflective vinyl film for high visibility.

How Thick Are License Plates?

A typical metal license plate is approximately 1.0 to 1.2 millimeters (0.04 inches) thick.

The thickness of a standard license plate is remarkably consistent.

This specific thickness is a careful balance: It provides enough structural rigidity to prevent the plate from bending, vibrating, or warping easily during use.

It remains thin enough to be cut, stamped, and embossed efficiently by high-speed machinery without requiring excessive force.

Detailed Breakdown by Material

Standard Metal Plates (Most Common)These are made from aluminum or, less commonly, steel.

Aluminum: This is the most common material for modern plates. It's lightweight, corrosion-resistant, and easy to stamp.

Thickness: 0.036 - 0.040 inches (approx. 0.9 - 1.0 mm)

Steel: Older plates and some specialty or temporary plates are made from steel. They are heavier and more prone to rust.

Thickness: Slightly thicker, often around 0.042 - 0.048 inches (approx. 1.06 - 1.22 mm)

Flat Plates (Digital Printed)

Many modern plates, particularly in Europe, are flat. They are made of aluminum but are not embossed. Instead, the design and registration number are printed directly onto the surface.

Thickness: The base aluminum is the same, around 1.0 mm, but the entire surface is flat.

Plastic and Temporary Plates

Plastic (e.g., dealer tags, some motorcycle plates): These are significantly thinner and more flexible.

Thickness: Typically around 0.5 mm or less.

Paper/Cardboard Temp Tags: These are not rigid and are only as thick as a heavy cardstock, usually around 0.2 - 0.3 mm.

Why Thickness Matters:

Practical ConsiderationsFrame Compatibility: Plate thickness is standardized so they fit into all license plate frames and holders without issue.

Automatic Readers: Law enforcement and toll booth cameras rely on a consistent, flat (or predictably embossed) surface to reliably read plate numbers. A standardized thickness ensures the plate sits correctly in its mount.

Durability: The specified thickness provides a balance between being lightweight enough for easy handling and rigid enough to resist bending, warping, or cracking under normal conditions (like car washes or minor impacts).

Manufacturing: The metal must be thick enough to be stamped without tearing but thin enough to be embossed efficiently.

In conclusion, if you need a measurement for a project like designing a bracket or a frame, you can safely plan for a thickness of 1 mm (0.04 inches).

What is the Size of a Typical License Plate?

While dimensions can vary slightly by country, a "typical" license plate size is based on the North American standard.

Here's a detailed breakdown of the most common license plate sizes around the world.

For the United States and Canada: 12 inches by 6 inches (In millimeters: 305 mm x 152 mm)(In centimeters: 30.5 cm x 15.2 cm)

This is the standard size for nearly every state, province, and territory for passenger cars.

Detailed Breakdown by Region and Vehicle

1. North America (USA, Canada, Mexico)

The North American standard is the most common reference point.

Passenger Cars: 12 × 6 inches (30.5 × 15.2 cm)

This is the universal size for all 50 US states, Canada, and Mexico.

Motorcycles: 7 × 4 inches (17.8 × 10.2 cm)

This is the most common size, though some states may have slight variations.

Large Trucks & Commercial Vehicles: Some larger vehicles may use the same 12"x6" plate, but others might have a larger, square plate.A common larger size is 12 × 12 inches (30.5 × 30.5 cm).

2. European Union & Many Other Countries

The EU has a standardized format to facilitate travel and identification across member states.

Passenger Cars:520 × 110 mm (20.5 × 4.3 inches)

This is the "long, thin" rectangle commonly seen on European cars. Some non-EU European countries (like Switzerland and Norway) also use this size.

Motorcycles: 210 × 140 mm (8.3 × 5.5 inches) or similar.

Motorcycle plate sizes can vary more between European countries.

3. Australia & New Zealand Australia:

Australia: Standards vary by state, but the common size for passenger vehicles is 372 × 134 mm (14.6 × 5.3 inches).

New Zealand: The standard size is 360 × 120 mm (14.2 × 4.7 inches).

4. Japan

Passenger Cars:A common class of passenger car uses a plate sized 330 × 165 mm (13.0 × 6.5 inches).

Japan has different plate sizes for different vehicle classes (e.g., kei cars, light vehicles), but they generally fall near this dimension.

5. Other Regions

United Kingdom (Pre-2001): Before adopting the EU standard, the UK used a size of 520 × 111 mm.

Many Asian, African, and South American countries often follow either the North American (12x6 in) or European (520x110 mm) standard, depending on their historical influences and trade partnerships.

Why Standardization Matters

Standardization is crucial for several reasons:

Vehicle Design: Car manufacturers design rear bumpers and mounting points to fit the standard plate of the market they are selling to.

Law Enforcement & Automation: Toll booths, traffic cameras, red-light cameras, and automatic license plate readers (ALPRs) rely on a predictable plate size and layout to function accurately.

Accessories: The market for license plate frames, covers, and holders depends on these standardized sizes.

Summary Table of Common License Plate Sizes

| Region | Vehicle Type | Size (Inches) | Size (Millimeters) | Remarks |

| North America (USA, Canada, Mexico) | Passenger Cars | 12 × 6 | 305 × 152 | Standard across all 50 US states, Canada, and Mexico |

| Motorcycles | 7 × 4 | 178 × 102 | Most common size, with minor variations possible in some states | |

| Large Trucks/Commercial | 12 × 6 or 12 × 12 | 305 × 152 or 305 × 305 | Some vehicles may use larger square plates | |

| European Union & Others | Passenger Cars | 20.5 × 4.3 | 520 × 110 | Standard EU format, also adopted by non-EU countries like Switzerland and Norway |

| Motorcycles | ~8.3 × 5.5 | ~210 × 140 | Motorcycle plate dimensions vary more across European countries | |

| Australia | Passenger Cars | 14.6 × 5.3 | 372 × 134 | Standards vary by state, but this is a common size |

| New Zealand | Passenger Cars | 14.2 × 4.7 | 360 × 120 | National standard size |

| Japan | Passenger Cars (Common) | 13.0 × 6.5 | 330 × 165 | Different vehicle classes (e.g., kei cars) have specific size requirements |

| United Kingdom (Pre-2001) | Passenger Cars | 20.5 × 4.4 | 520 × 111 | Previous UK standard before adopting EU dimensions |

| Other Regions | Passenger Cars | Varies | Varies |

In conclusion, if you are in the United States or Canada and need a measurement for a project (like buying a frame or designing a mounting bracket), the standard 12 x 6 inches is the dimension you should use. Always double-check for any local variations, especially for motorcycles or specialty vehicles.

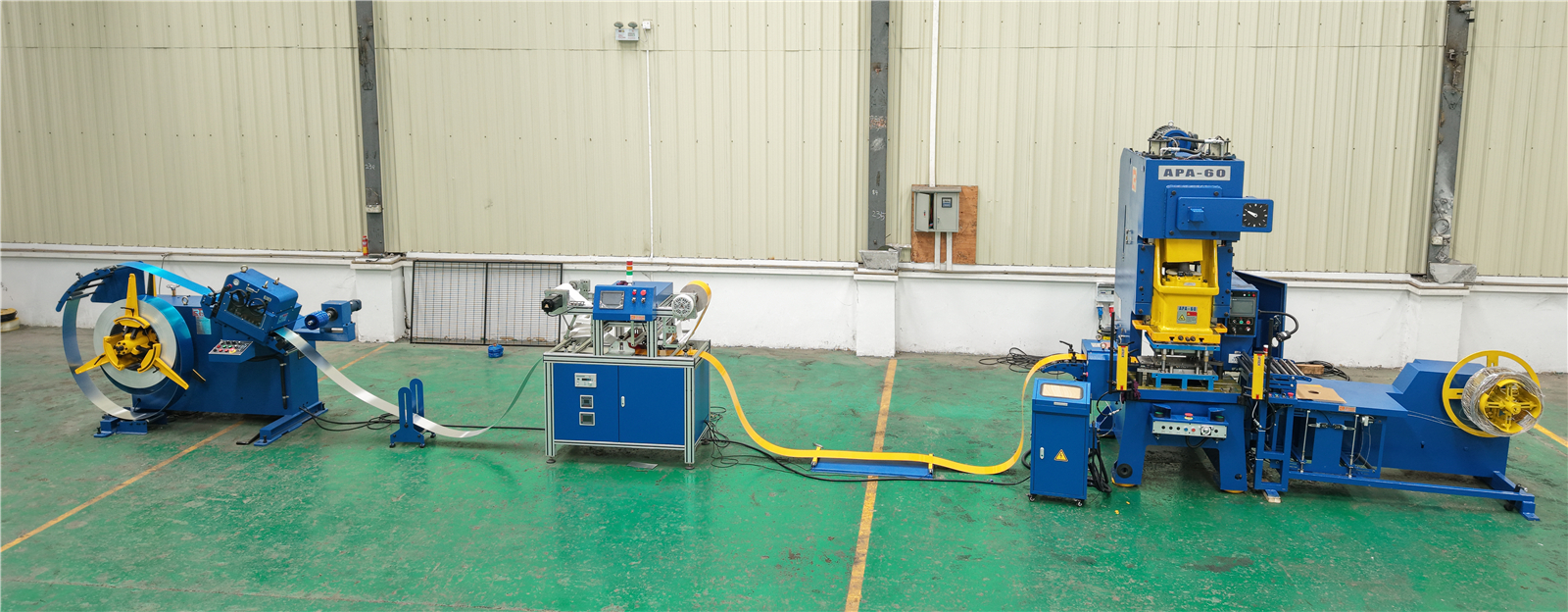

How Do They Make License Plates?

The manufacturing process is a highly automated and secure operation, often taking place in state-run or contracted correctional facilities. To provide a comprehensive understanding of SUNRUI MACHINE's Car License Plate Production Stamping Line, let's delve into the detailed specifications and functionalities of each piece of equipment involved in the automated production process.

Step 1: Coiling and Blanking

Large rolls of plain aluminum coil are fed into a press that cuts them into individual, rectangular blanks of the correct size (e.g., 12" x 6"). These blanks are stacked and ready for the next stage.

The below machines will be recommend for blanking by SUNRUI machine.

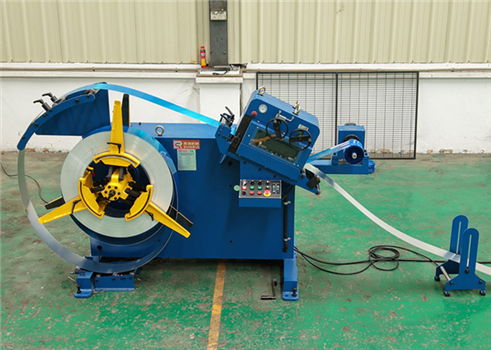

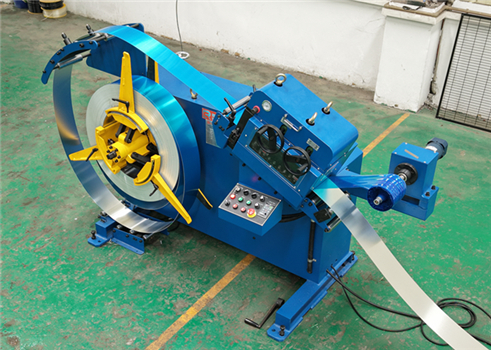

High Precision Decoiler & Straightener 2-in-1 Machine

Functionality: This dual-function machine combines the processes of decoiling and straightening into one unit, ensuring efficiency and space-saving in the production line.

Decoiling: The machine unwinds the raw material (usually a coil of metal) smoothly, preventing any deformation or damage to the material.

Straightening: Equipped with multiple rollers, it straightens the metal sheet as it unwinds, removing any bends or twists that could affect the subsequent stamping process.

Features:

Adjustable straightening rollers to accommodate different material thicknesses.

Automatic tension control for consistent feeding without material slack.

Compact design for easy integration into existing production lines.

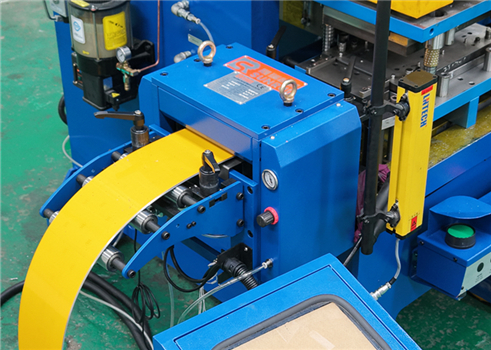

NC Servo Feeder Machine

Functionality: The NC (Numerical Control) Servo Feeder Machine is designed to provide precise and stable feeding of the material into the stamping press, ensuring optimal performance.

Precision Feeding: Utilizes servo motor technology to deliver accurate pre-set lengths of material, which is crucial for maintaining consistency in each stamped part.

Speed Control: The machine allows for variable speed adjustments to match the production requirements, enhancing flexibility.

Features:

User-friendly interface for easy programming and operation.

Built-in safety features, including emergency stop buttons and sensors to prevent material jams.

Quick-change tooling for efficient adaptation to different production runs.

Step 2: Cleaning and Pre-Treatment

The aluminum blanks are washed and chemically treated to remove any oils, dirt, or oxides from the surface. This is a critical step to ensure the reflective coating will adhere properly later on.

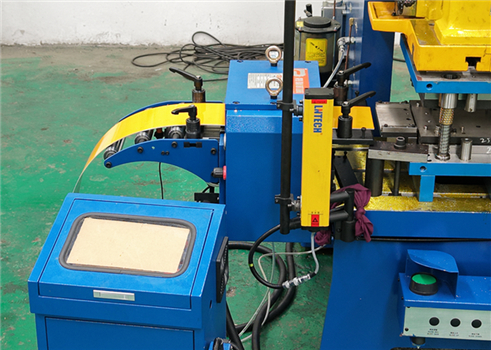

The below machines will be recommend for filming by SUNRUI machine.

Auto Filming Machine

Functionality: The Auto Filming Machine automates the application of protective film to the license plates, ensuring uniform coverage and reducing defects associated with manual application.

Uniform Tension Application: The machine applies the film at a consistent tension, preventing bubbles or wrinkles that can occur when applied manually.

Heating Mechanism: Features an integrated heating element that softens the film for better adhesion, improving durability and appearance.

Features:

Adjustable film width to accommodate various license plate sizes.

Automatic film roll replacement to minimize downtime during production.Real-time monitoring of film application for qualit control.

Step 3: Stamping/Embossing

The cleaned blanks are fed into a massive stamping press. A hardened steel die, with the reverse image of the required characters (e.g., "ABC 123"), stamps each plate with tremendous force. This process raises the characters, creating the familiar embossed look. For flat, digital-print plates, this step is skipped.

The below machines will be recommend for stamping by SUNRUI machine.

High Precision Stamping Press Machine (APA-60) with Progressive Die

Functionality: The APA-60 stamping press is the heart of the production line, responsible for shaping and embossing the license plates with high precision.

Progressive Die Design: This type of die allows multiple operations (cutting, bending, embossing) to be performed in a single pass, significantly increasing efficiency and reducing cycle time.

High-Speed Operation: Capable of delivering rapid strokes per minute, it maximizes production output while maintaining excellent quality.

Features:

Advanced control system for precise stroke adjustment and monitoring.

Robust construction to handle high-pressure stamping without deformation.

Safety features including guards and sensors to ensure operator safety.

Scrap Recoiler Machine

Functionality: The Scrap Recoiler Machine plays a crucial role in sustainability by efficiently collecting and recycling scrap materials generated during the production process.

Automatic Collection: As the production line operates, the machine automatically gathers scrap metal, preventing it from contaminating the work area.

Compact Design: Designed to minimize space usage while maximizing scrap collection efficiency.

Features:

Easy-to-use controls for monitoring scrap collection status.

High-capacity storage for extended production runs without frequent emptying.Integration capabilities with other machines in the production line for seamless operation.

Step 4: Reflective Coating Application

The embossed plates are now dull gray. They move through a machine that applies a sticky, pre-cut vinyl film in a process known as "sheeting." This film is highly reflective and comes in standard colors (like white for background or yellow for certain plates). A roller firmly presses the film onto the plate, ensuring no air bubbles are trapped and that it conforms to the embossed characters.

Step 5: Baking and Curing

The sheeted plates pass through an oven. The heat activates adhesives on the reflective sheeting, permanently bonding it to the aluminum substrate and ensuring long-term durability.

Step 6: Printing

For embossed plates, the raised characters are now a plain reflective color. They move under an ink-roller printer which applies paint specifically to the raised surfaces, creating the contrasting character color (e.g., black on white). For flat plates, a high-speed, high-resolution digital printer directly prints the entire design (background and characters) onto the reflective sheeting.

Step 7: Baking Again

The painted or printed plates go through another oven to cure and harden the ink, making it scratch and weather-resistant.

Step 8: Quality Control and Packaging

Automated cameras and sensors inspect each plate for defects like misprints, scratches, or imperfect sheeting. Approved plates are then counted, stacked, and packaged for shipment to motor vehicle agencies.

Conclusion

The integration of these advanced machines in SUNRUI MACHINE's Car License Plate Production Stamping Line not only enhances productivity and efficiency but also ensures high-quality output and reduced operational costs. By automating the entire process, manufacturers can achieve a competitive edge in the automotive market, paving the way for increased scalability and profitability.

For manufacturers looking to modernize their operations, each of these machines represents a vital component in achieving a streamlined and effective production process. Contact SUNRUI MACHINE today to learn how our cutting-edge technology can transform your license plate manufacturing!

SUNRUI car license plate production stamping line Video