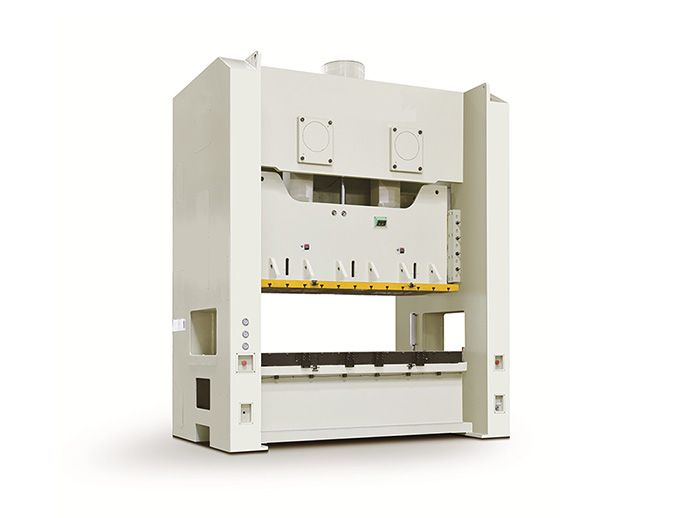

Stamping Press

What is stamping press machine?

A stamping press machine is a type of machine that is used in the manufacturing industry for shaping and cutting metal into the desired shape or form. It is commonly used in a process known as stamping, which involves the use of dies and punches to cut and shape the metal. A stamping press machine can be either mechanical or hydraulic, and it can be used to produce various products with high precision and speed.

The stamping press machine works by applying a force to the metal, typically through the use of a ram or plunger. The force causes the metal to be shaped or cut into the desired form, which is determined by the shape of the dies and punches that are used.

Stamping press machines are used in a wide range of industries, including automotive, aerospace, appliance, and electronics. They can produce a variety of products, including automotive body parts, electrical contacts, and electronic components.

Types of stamping presses

The two common types of presses include mechanical presses and hydraulic presses. Typically, the press is connected to an automatic feeder that feeds the sheet metal into the media in the form of coils or blanks.

Mechanical

Mechanical presses use motors connected to a flywheel to transmit and store energy. Depending on the particular press, they have punch sizes ranging from 5 mm to 500 mm. The speed of mechanical presses also varies, usually between 20 and 1,500 strokes per minute, but they tend to be faster than hydraulic presses. These presses range in size from 20 tons to 6,000 tons. They are ideal for making shallower and simpler parts from sheet metal coils. They are often used for progressive and transfer stamping for high-volume production.

Hydraulics

Hydraulic presses use pressurized hydraulic fluid to apply force to the material. The hydraulic piston discharges the fluid at a force level proportional to the diameter of the piston head, allowing for advanced control of the amount of pressure and more consistent pressure than mechanical presses. In addition, they have adjustable stroke and speed capabilities and can typically provide full power at any point in the stroke. These presses typically range in size from 20 to 10,000 tons, with stroke sizes ranging from approximately 10 mm to 800 mm.

Hydraulic presses are typically used in smaller production runs to make more complex and deeper stampings than mechanical presses. They offer greater flexibility due to adjustable stroke lengths and controlled pressures.

Are you seeking a cutting-edge solution to elevate your metal fabrication processes and stay ahead in the fiercely competitive manufacturing industry? Look no further than our state-of-the-art stamping press machine. Designed with your concerns in mind, our machine combines precision, efficiency, and versatility to revolutionize your production line.

Precision: Our stamping press machine boasts advanced technology and meticulous engineering, ensuring precise shaping and cutting of metal into your desired forms.

Efficiency: Our stamping press machine is built to optimize your manufacturing efficiency. Its streamlined design, coupled with intelligent automation features, enables rapid cycle times, reducing production lead times and increasing output.

Versatility: Stamping press machine accommodating a wide range of metal materials and thicknesses. From simple components to intricate designs, our machine effortlessly handles diverse stamping requirements.

Durability and Reliability: Crafted from premium materials and utilizing robust components, our machine ensures exceptional durability and reliability. Minimize maintenance disruptions and enjoy uninterrupted operation, maximizing your manufacturing uptime and profitability.

Safety: Our stamping press machine incorporates comprehensive safety features to protect operators during operation. From advanced sensors and interlocks to ergonomic design elements, we prioritize safety without compromising productivity.

Expert Support and Training: Our team of experts provides comprehensive support, including installation, training, and ongoing assistance.