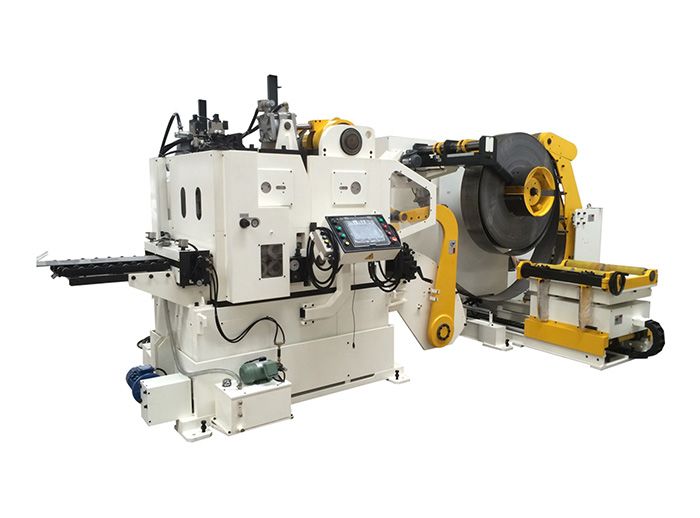

Decoiler Straightener Feeder

The decoiler straightener feeder for your complete stamping line solution

The decoiler straightener feeder can be combined with coil stamping lines, fixed length lines and stamping systems from all manufacturers. The coiled material passes from the decoiler through the left and right free guide rolls with advanced photoelectric sensors to maintain circulation. The coil is fed from the bottom up through the decoiler system, through the unwind device, head leveling device, pinch feed rollers, work rollers, and feed rollers for a good smooth feeding of the coil material.

The 3-in-1 decoiler straightener feeder has different structures for different situations. The main structures are as follows.

1. High-speed 3-in-1 decoiler straightener for drop line. Speed up to 40m/min.

2. High-precision 3-in-1 uncoiler straightener feeder with long feeding length (pitch greater than 1.5m) and high-precision parts, sometimes used for progressive dies without guides.

3. Straightening feeding head can be turned upward to clean the rollers. Mainly used for aluminum and hot rolled material.

4. The engagement depth of the upper and lower rolls of the straightening machine is adjusted by a servo motor or hydraulic motor to suit different thicknesses. The numerical value can be saved to facilitate easy and fast adjustment next time.

5. The upper and lower rolls are made of PU. It is suitable for soft materials or materials with high requirements for surface quality, such as aluminum, brass or copper, etc.

6. The panel language can be translated into different languages according to customers' requirements, which is convenient for operators to operate.

The 3-in-1 decoiler straightener feeder is highly intelligent and fully automatic equipment. Humanized design, including uncoiler, straightener and servo feeder, all in one, makes full use of valuable factory space and improves production efficiency. It can be combined with various brands of stamping systems, fixed-length lines, robot lines and presses. It is widely used in industries such as auto parts, household appliances, and furniture parts manufacturing.

Our 3-in-1 decoiler straightener feeder is suitable for all kinds of coils, including cold rolled steel, hot rolled steel, mild steel, stainless steel, aluminum, copper, and especially high strength steel. There is a considerable range of applications, with coil widths from 0.5mm to 9.0mm and coil thicknesses from 50mm to 1800mm. depending on the coil characteristics, a variety of coil feeding systems can be perfectly selected to meet unique requirements.

Our decoiler straightener feeder offers the advantage of excellent straightening capacity

Our decoiler straightener feeder offers the advantage of excellent straightening capacity and easy operation. Easier uncoiling and reel change with automatic uncoiler and reel loading carts. The coil front end is automatically fed into the straightener section. All straightening rolls are hard chrome plated and precision ground. The gap between the upper and lower rolls is finely adjusted by a worm gear. In addition, the unique flip-top design of the straightening machine allows workers to clean the straightening rolls easily. The feeding section is equipped with reliable AC servo motors. Closed-loop encoder feedback circuit ensures feed length accuracy. Multi-language operating system and user-friendly operation interface make setup quick and easy. Feeding speed up to 16~24m/min. Robust design reduces most maintenance and improves safety. The time-saving, space-saving and labor-saving features reflect the high economic use of the 3-in-1 uncoiler straightening machine. As a result, it is becoming increasingly popular around the world.

FAQ

1. What is Sunrui Machinery's experience in manufacturing decoiler straightener feeders?

We have been manufacturing and supplying decoiler straightener feeders for over 20 years and has extensive experience in the field. We have a team of experienced engineers who are dedicated to ensuring that equipment meets the highest standards of quality and reliability.

2. What is the price range of Sunrui Machinery's decoiler straightener feeders?

The price of our decoiler straightener feeders varies depending on the specific model and customization options required. Our decoiler straightener feeder is competitively priced in the market, and they provide quotes based on the specific needs and requirements of each buyer.

3. Can Sunrui Machinery customize its decoiler straightener feeders to meet specific requirements?

Yes, Sunrui Machinery can customize its decoiler straightener feeders to meet the specific needs and requirements of its customers. They have a team of experienced engineers who can work closely with buyers to design and manufacture a machine that meets their unique specifications.

4. What is the lead time for delivery of Sunrui Machinery's decoiler straightener feeders?

The lead time for delivery of Sunrui Machinery's decoiler straightener feeders can vary depending on the specific model and customization options required. We strive to provide accurate lead times during the quoting process and work closely with customers to ensure that their equipment is delivered on time.

5. What is the warranty period for Sunrui Machinery's decoiler straightener feeders?

We offer a 12-month warranty period for its decoiler straightener feeders, which covers any defects in materials or workmanship. We also provide ongoing support and maintenance services to ensure that equipment continues to perform at its best.

6. How can I get a quote for a decoiler straightener feeder from Sunrui Machinery?

Contact us to get a quote for decoiler straightening feeder, you can contact us directly through our website or by phone or email. We will ask for specific details about your needs and requirements and provide a custom quote based on these details.

Sunrui Machinery's 3-IN-1 decoiler straightener feeder is accurate, handles materials of various widths and thicknesses, and reduces waste. Our web feeding systems are ergonomically designed to provide more efficient operation and enhanced functionality to meet your specific pressroom needs.

View the features and specifications of our 3-in-1 decoiler straightener feeder below, then contact us for assistance in determining which decoiler straightener feeder you need.