Hydraulic Decoiler Machine

Applicable Material

Raw Material Type: Suitable for vary kind of coil material, such as Galvanized steel, Stainless steel, CR Steel, HR Steel, Galvanized steel, Stainless steel, Aluminum, Cooper etc.

Applicable Coil Width: 20mm-1300mm

Applicable Coil Thickness: 0.3-3.5mm

Coil Inner Diameter: 450-530mm

Coil Outer Diameter: 1200mm

Speed: 15m/min

Pressing arm and coil car for optional

Applications: Pressing Line/Metal Stamping Line/ Forming Line

Brief Profile of Hydraulic Decoiler Machine

The hydraulic decoiler machine typically consists of a sturdy frame with a spindle or mandrel to hold the metal coil, hydraulic cylinders to control the tightening and unloading of the coil, and a hydraulic loading car to facilitate the loading process of the metal coil onto the decoiler.

The hydraulic cylinders provide the necessary force to tighten the coil in place and slowly unwind the metal as it passes through the production line. The hydraulic loading car is used to move and load the metal coil onto the decoiler, which is then secured and tightened using the hydraulic cylinders.

Hydraulic decoiler machines are commonly used in large-scale manufacturing operations, including automotive, construction, and metal fabrication industries, where heavy-duty metal coils need to be processed.

Overall, the hydraulic decoiler machine significantly reduces the time and effort required to load and tighten metal coils, while ensuring efficient and safe material feeding for further processing.Hydraulic decoiler machine is suitable for weight over 2000kgs, are used to facilitate the work of operator and facilitate the inner tightening process, for higher weight rolled sheet metal that can not be done used using manual tightening system.

When the hydraulicdecoiler is used, the process of loading the roll onto the decoiler will be facilitated and speeded up. Using a hydraulic loading car will further facilitate the loading process and shorten the time as well.

Application of Hydraulic Decoiler Machine

Hydraulic decoiler machine is suitable for all kinds of metal sheet stamping, such as the hardware parts, home appliances, furniture hardware, motorcycle accessories, mobile phone accessories, computer accessories and so on.

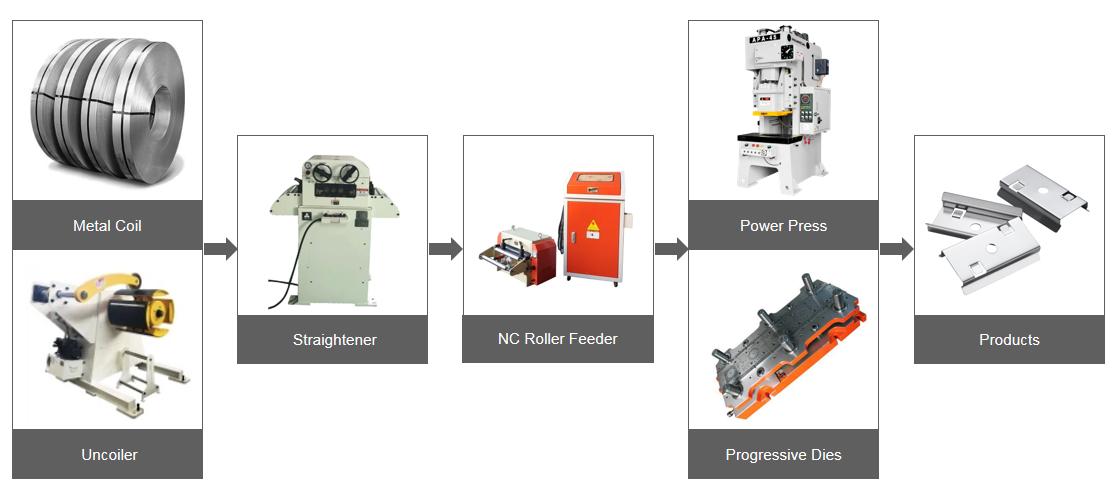

The configuration of metal sheet stamping line.

Step-1: Hydraulic decoiler machine, Loading coil and uncoilling coils

Step-2: Metal straightener machine, leveling the strips and lead it to feeder machine.

Step-3: Nc Servo Feeder machine, Feed coil to press machine.

Step-4: Power press machine with the moulds, pressing to the end product.

Specification of Hydraulic Decoiler Machine

| Model | MT-400F | MT-500F | MT-600F | MT-700F | MT-800F | MT-1000F | MT-1200F |

| Coil Width | 200 mm | 300 mm | 400 mm | 500 mm | 600 mm | 700 mm | 800 mm |

| Coil Thickness | 0.1 mm - 3.2mm | ||||||

| Coil I.D. | 450-530 mm | ||||||

| Coil O.D. | 1200 mm | ||||||

| Coil Weight | 1000 kgs | 1500 kgs | 2000 kgs | 3000 kgs | 5000kgs | ||

| Expansion | Hydraulic Expansion | ||||||

| Pressing Arm | Pneumatic Type Pressing Arm | ||||||

| Inverter | Delta, Taiwan | ||||||

| Speed | 16 m/min | ||||||