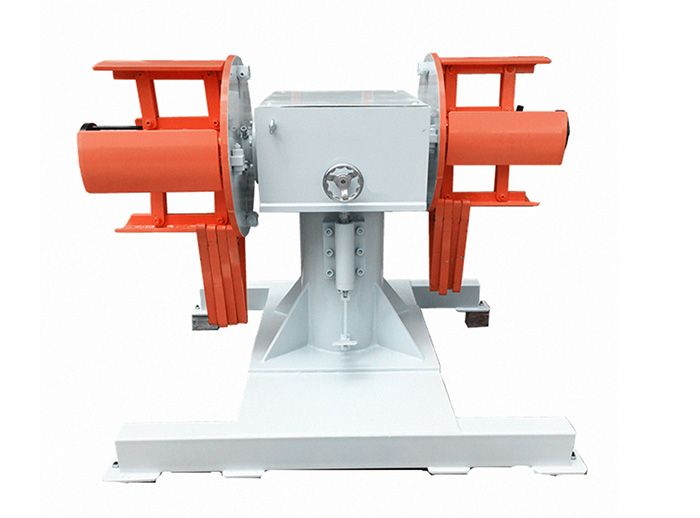

Double Head Decoiler Machine

Applicable Material

Model No.: DBMT

Applications: Pressing Line/Metal Stamping Line/Forming Line

Applicable Coil Width: 20mm-300mm

Applicable Coil Thickness: 0.3-3.5mm

Coil Inner Diameter: 450-530mm

Coil Outer Diameter: 1200mm

Speed: 60m/min

Mandrel Expansion: Manual

Without Power

Application: Uncoiling the coils

Ideal for high speed lamination stamping line

Brief Profile of Double Head Decoiler Machine

The double head decoiler machine drives one of the rolls to uncoil the metal strip, while the other waits as a backup. When the driven roll is exhausted, the backup roll is readily connected to the driver within a very short period of time, minimizing production downtime. This approach allows for longer periods to load another spare roll, further reducing production time.

The double head decoiler machine is an ideal solution for production plants where speed and continuity are critical, particularly in serial manufacturing. It is commonly configured with an S-loop straightener, high-speed gear machine, and H-frame high-speed press machine, making it ideal for motor rotor and stator lamination stamping.

Overall, the double head decoiler machine efficiently and reliably uncoils metal strips while minimizing downtime and maximizing throughput, making it a valuable tool for large-scale manufacturing operations.

Application of Double Head Decoiler Machine

Usually, double head decoiler machine is equipped with the high speed press machine. This high speed coil feeding line combined double head decoiler, s-loop straightener, and cam feeder, speed can reach 60m per minute, design for motor and EI lamination stamping.

The configuration of high speed press line for Motor and EI lamination

Step-1: Double Head Decoiler machine, Loading coil and uncoilling coil.

Step-2: High speed S Loop Straightener machine, leveling the strips.

Step-3: High speed Cam Feeder machine, Feed coil to press machine.

Step-4: High speed press machine with the moulds, pressing to the end product

Specification of Double Head Decoiler Machine

| Model | DBMT-200 | DBMT-300 |

| Coil Width (mm) | ~200 | ~300 |

| Coil Thickness (mm) | 0.1 - 1.6 | |

| Coil I.D. (mm) | 450 - 530 | |

| Coil O.D. (mm) | 1200 | |

| Loading Capacity (kgs) | 500 + 500 | 1000 + 1000 |

| Spindle Expansion | Manual | |

| Pressing Arm | Optional | |

| Power (HP) | Non-motorized | |

| Inverter | Without | |