Uncoiler Straightener Feeder MFL2 (0.3-3.2mm)

Applicable Material

Raw Material Type: Hot-Rolled Metal steel, Cold-Rolled Metal steel, Galvanized Metal steel ,Stainless Steel etc.

Coil Width: 100-1300 mm

Material Thickness: 0.3.3.2 mm

Yield Strength: ≤245 N/mm2

Tensile Strength: ≤392 N/mm2

Speed: 0-22m/min

Brief Profile of Uncoiler Straightener Feeder

SUNRUI Coil Straightener Feeder MFL2 (0.3-3.0MM) machine consists of three main components: the uncoiler, the straightener, and the feeder. The uncoiler is responsible for feeding the metal coil into the machine, while the straightener straightens the metal coil to ensure consistent feeding into the machine. The feeder is responsible for feeding the straightened metal coil into the press or punching machine, where it is cut into desired shapes.

SUNRUI Servo Straightener Feeder MFL2 (0.3-3.0MM) machine is designed to handle a variety of materials, including stainless steel, carbon steel, aluminum, and copper. It is commonly used in the production of metal parts for various applications, including automotive, electronic, and household appliances.

SUNRUI Uncoiler Straightener Feeder MFL2 (0.3-3.0MM) machine has a compact design and can be easily integrated into existing production lines. It is also equipped with advanced control systems and sensors that ensure precise processing of metal coils into flat sheets or blanks.

Overall, the MFL2 (0.3-3.0MM) uncoiler straightener feeder is a reliable and efficient machine for metalworking processes.

Application of of Uncoiler Straightener Feeder

● AUTOMOTIVE

Manufacture of equipment for metal stamping of small and thin automotive parts and other parts.

● BUILDING & HOUSEHOLD

Feeding lines to produce a variety of metal components for the building and household sector and derivatives. Parts like braces, clamps, straps, locks and hinges for doors,furniture hardware, knifes, cooking ware carpentry parts, metal supports, perforated plates, etc ..

● HOME APPLIANCE & ElECTRONICS

Installations for the manufacture of parts for household appliances sector or white goods. Metal pieces like, electric cabinet, shells and covers, trays, guides, caps, supports, brackets, handles, etc ...

● ILLUMINATION

Many solutions for the blanking of metal parts for lighting sector. Several parts such as housings, panels, brackets, feet, arms, buttons, diffusers, etc ...

Features of of Uncoiler Straightener Feeder

● Reliable Structure Design

Super large scale and plenty of advanced quality control measures including CNC machining, grinding machine, boring machine and Lathe machine equipment and various precision testing instruments from Germany, Japan and Taiwan. It can ensure the high precision and quality of all parts of machine.What's more, all of main body makes surface treatment with our shot blasting machine before they are painted. With our shot blasting machine treatment, the machine surface is excellent for painting.they blast onto the surface of work piece with shots to clean and beautify the surface. The shot blasting also enhances the pressure stress of work piece surface and extends the lifespan.We also use high-end vehicle oil paint for our machine to have high level of painting quality and you don’t need to worry about broken painting problem under extremely nasty working environment.

● Modular control, simple and smart operation

SunRui MFL series compact coil feed line is not only a simple integration of decoiling, leveling and feeding machine into one unit, but also emphasizes highly integrated control in control operations.The control of the material decoiler hydraulic station, the hydraulic coil car, the decoiler driven motor, the inverter and the feeding servo system are all connected with the PLC control module system and the basic parameters can be set up in the touch screen. The simple digital control of the 7-inch high-precision touch screen makes the use of the compact coil feed line adjustment machine very simple and convenient, and the degree of intelligence is extremely high.

● Space saving and easy installation and low maintain

SunRui MFL series compact coil feed line save space structure designed is not only a simple integration of decoiling, leveling and feeding machine into one machine, but also emphasizes highly integrated control in control operations.it can achieves simple operation, low maintenance, complete functions, energy saving and high completeness.

● High precision straightening and feeding performance

For the separate independent type decoiler straightener feeder machine, there will be a loop between each machine, means that all of them need an inverter for speed control and single of sensor for movement, even so, the movement will not be fully synchronized, which will affect the precision of feeding. Decoiler straightener feeder coil feeding line can synchronize these three parts, and be controlled by high precision servo driven and PLC system, which ensure a high servo feed accuracy.

Specification of Uncoiler Straightener Feeder

| Model | MFL2-400 | MFL2-500 | MFL2-600 | MFL2-800 |

| Stock Width(mm) | 50-400 | 50-500 | 50-600 | 50-800 |

| Stock Thickness(mm) | 0.3-3.2 | |||

| Max.Coil Weight(kg) | 3000 | 5000 | 5000 | 5000(7000) |

| Max.Coil O.D.(mm) | 1200 | |||

| Coil I.D.(mm) | φ470-520 | |||

| Feed Length(mm) | ~500* | |||

| Max. Line Speed(m/min) | 16-24 | |||

| Straightener Rolls(pieces) | φ48mm*11 (upper 6/ lower 5) | φ68mm*7(upper4/ lower 3) | ||

| Feed Rolls (set) | φ68mm*2 (upper 1/ lower 1) | φ88mm*2 (upper 1/ lower 1) | ||

| Servo Motor | AC2.9 | AC2.9 | AC4.4 | AC4.4 |

| Mandrel Expansion | hydraulic | |||

| Deoiler Motor(kw) | 1.5 | 2.2 | 2.2 | 3.7 |

| Power(V) | 3 Phase 220V/380V/440V/50HZ | |||

| Operating Air(Mpa) | 0.49 | |||

| Straightener Capacity( Yield strength σs≤245N/mm² ,Tensile strength σb≤392 N/mm²) | ||||||||

| Model | Thickness(mm) | |||||||

| 0.3~1.4 | 1.6 | 1.8 | 2 | 2.3 | 2.8 | 3.2 | ||

| Coil Width(mm) | MFL2-400 | 400 | 300 | 230 | 150 | 110 | ||

| MFL2-500 | 500 | 400 | 360 | 300 | 230 | 150 | 110 | |

| MFL2-600 | 600 | 470 | 360 | 300 | 230 | 150 | 110 | |

| MFL2-800 | 800 | 470 | 360 | 300 | 230 | 150 | 110 | |

Main Parts of Uncoiler Straightener Feeder

Coil Car

● Coil car is one of the optional for the customer, It is installed on the side of the decoiler part, and can automatically feed the coil into the straightener-feeder accurately and fastly.

● Wear-resisting loading surface through the sand blasting process.

● Safety arms to prevent coil falling.

● Hydraulic cylinder drive the coil car lifting up and down.

● Hydraulic motor drive the coil car move forward and backward.

● Remote button control and touch screeen control

Uncoiler Machine

● The uncoiler is designed for coils with an outside diameter of up to 1200mm. The coil is placed on spindle and expanded manually.

● Spindle expansion range: Φ470-Φ520mm.

● Decoiler is Driven is by AC motor with an inverter

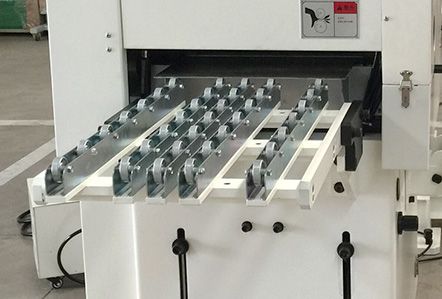

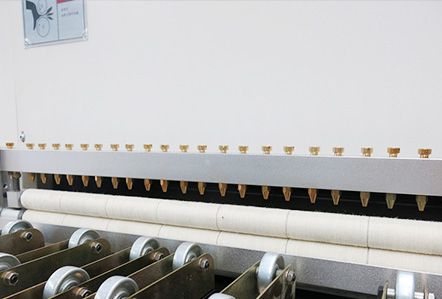

High Precision Straightening and Feeding Machine

● The straightener feeder parts is straightening the coil strips and feeding it into the stamping press and dies according to the fixed length controlled by PLC.

● Given the difference in coil at the beginning of rollers and the end of roller, it is usually necessary for an operator to always be monitoring straightening operations, and to manually carry out corrections to ensure a high degree of precision in straightening.

● Straightener Roll Material :GCr15 ,Thickening plating and Gringding processing. Hardness :HRC58-60°, roller surface is done plough electroplating processing.

Discharging Support Bracket

● The outlet support bracket is used to deliver the straightening strips to press die smoothly.

● When the coil material is thin thickness or soft material , or the distance between straightener-feeder and stamping dies is

long, the strip can not be delivered the strip head into the die successfully, the support bracket will help to reach it.

● The length of the support bracket is adjustable to meet different dimensions of stamping press machine and dies.

Automatic Lubrication Unit (Option)

● Lubrication of steel strip before stamping will protect the stamping dies from damaging and prolonging the uselife.

● The automatic lubrication system is automatically controlled, with an oil loop recycling system, which will save oiling cost and prevent leakage.

Video of Uncoiler Straightener Feeder