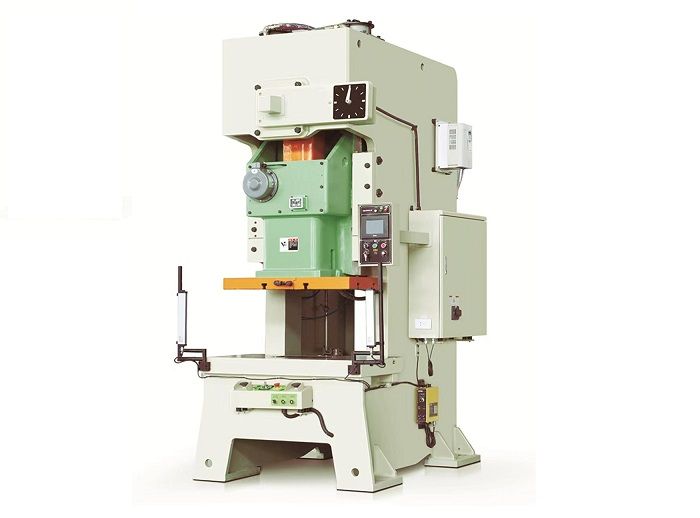

Single Crank C Frame Press Machine

Applicable Material

Material Type: Suitable for vary kind of coil material, such as Galvanized steel, Stainless steel, CR Steel, HR Steel, Galvanized steel, Stainless steel,Aluminum, Cooper etc.

Capacity: 15 ton to 400ton

PLC control.

Dry clutch or Wet clutch for optional.

Hydraulic overload protected.

Both mechanical and electric cam control.

Auto lubricated.

Customized bigger table better for big sheet stamping or progressive die stamping process.

Light curtain, inverter, air cushion are optional.

Brief Profile of Single Crank C Frame Press Machine

The machine consists of a frame made of high-quality steel plates, die tooling, and a crankshaft mechanism, which is operated by a motor. The motor drives the flywheel, which then drives the crankshaft, connecting rod mechanism, clutch, and transmission gear to move the slider up and down.

The C-shaped frame design of the machine provides maximum accessibility to the workpiece and allows for easy handling of the materials during production or maintenance. The machine is designed to withstand heavy loads and rapid cycling, with an adjustable stroke of the slider in 8 gears to meet the processing requirements of various dies.

The machine is designed with high rigidity in the machine frame, with the high precision power press body welded of quality steel sheet and treated by tension elimination. This improves the stability and reliability of the precision of the machine.

Other functions of the power press machine include keeping the transmission center and machine center in uniformity for guaranteed precision of pressing, the use of symmetrical boards with balancer to ensure stable and smooth machine running, and the precision of mold adjusting up to 0.1mm for safety, reliability, and convenient adjustment.

Overall, the single crank press machine is a reliable, energy-efficient, and cost-effective solution for small and medium-sized metalworking and stamping operations, with high precision and durability.

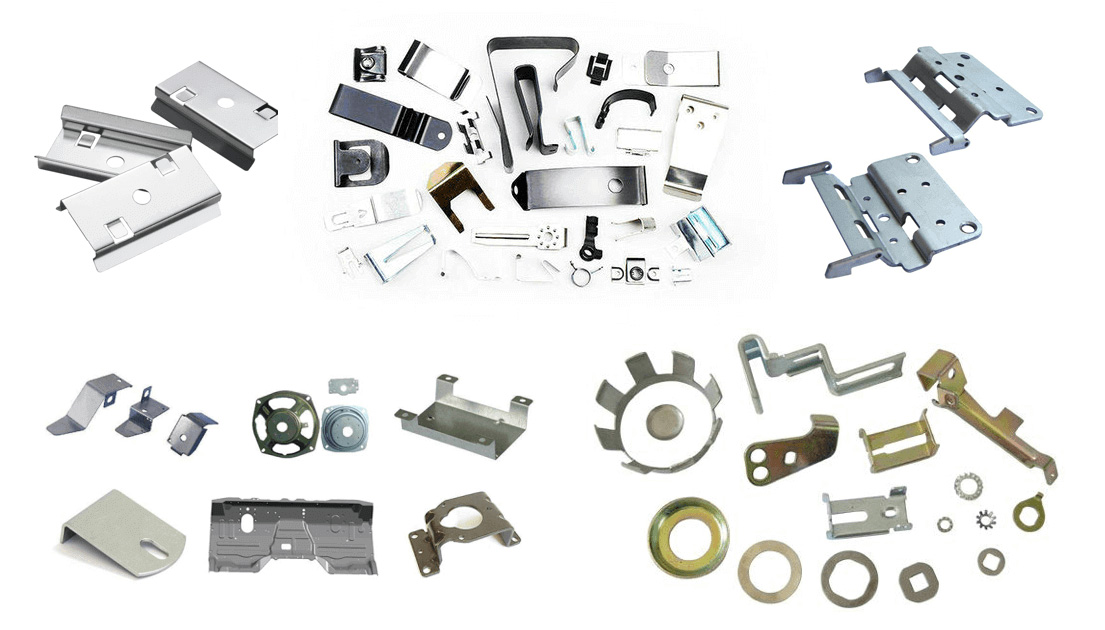

Application of Single Crank C Frame Press Machine

Single crank C Frame press machine is suitable for all kinds of metal sheet stamping, including the hardware parts, home appliances, furniture hardware, motorcycle accessories, mobile phone accessories, computer accessories and so on.

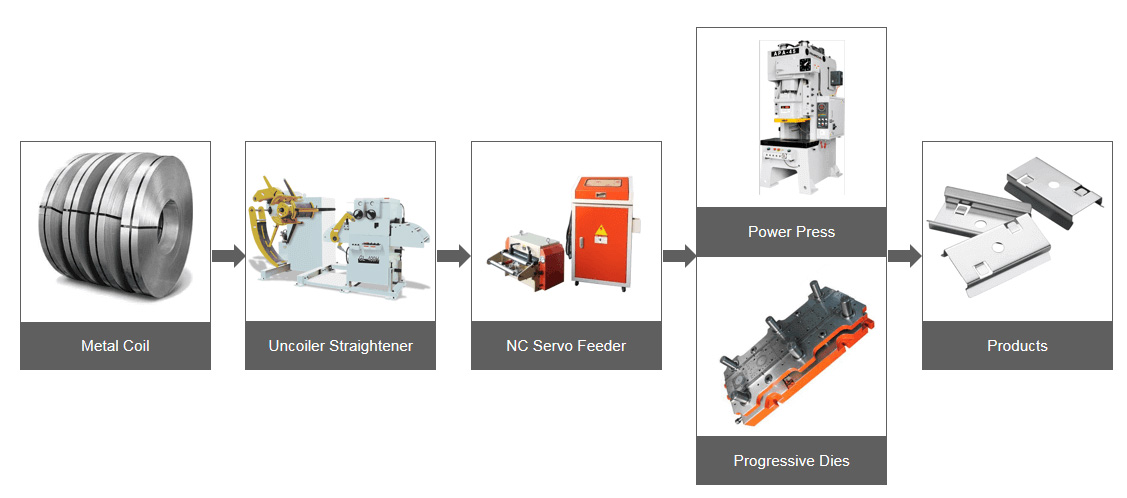

The configuration of metal sheet stamping line.

Step-1: Uncoiler straightener machine, Loading coil and uncoilling coil and level the strips.

Step-2: Nc Servo Feeder machine, Feed coil to press machine.

Step-3: Power press machine with the moulds, pressing to the end product.

Features of Single Crank C Frame Press Machine

The single crank C-frame press machine features a steel welded body that undergoes tempering treatment for high rigidity, accuracy, and stability. It has low integrated clearance and a small change in mold height, ensuring precision in operation.

The machine also has a small deviation of dynamic center, providing a long mold life and minimal deformation during press operation. The vertical located crankshaft design ensures a compact structure, and the crankshaft undergoes grinding treatment after high-frequency quenching.

The machine's lengthened rectangular guideway has a surface of bronze plate, ensuring high precision processing and high-efficiency operation to provide high-quality products. The implementation is also made easy with the fixed locking type six-surface guide way and a low-noise, safe, and reliable operating state.

The single crank C-frame press machine is a versatile and reliable solution for shaping, cutting, and punching a variety of sheet materials, providing high-precision and efficient operation.

Specification of Single Crank C Frame Press Machine

| C Frame Single Crank Press Machine | ||||||||||

| Model | APA-15 | APA-25 | APA-25 | APA-35 | APA-45 | APA-60 | ||||

| V Type | V Type | V Type | H Type | V Type | H Type | V Type | H Type | V Type | H Type | |

| Capacity(Ton) | 15 | 25 | 25 | 35 | 45 | 60 | ||||

| Rated Tonnage point(mm) | 1 | 3.2 | 3.2 | 1.6 | 3.2 | 1.6 | 3.2 | 1.6 | 4 | 2 |

| Stroke Per Variable(SPM) | 120-180 | 60-140 | 60-140 130-200 | 40-120 | 110-180 | 40-100 | 100-150 | 35-90 | 80-120 | |

| minute Fixed(SPM) | 130 | 110 | 110 | 85 | 75 | 65 | ||||

| Stroke(mm) | 60 | 80 | 60 | 30 | 70 | 40 | 80 | 50 | 120 | 60 |

| Die Height(mm) | 200 | 195 | 200 | 215 | 220 | 235 | 250 | 265 | 310 | 340 |

| Slide Adjustment(mm) | 50 | 50 | 50 | 55 | 60 | 75 | ||||

| Slide area(mm) | 300x230x50 | 300x230x50 | 300x230x50 | 360x250x50 | 400x300x60 | 500x360x70 | ||||

| Bolster Area(mm) | 680x300x70 | 680x300x70 | 680x300x70 | 800x400x70 | 850x440x80 | 900x500x80 | ||||

| Shank Hole(mm) | 38.1 | 38.1 | 38.1 | 38.1 | 38.1 | 50 | ||||

| Main Motor (kw.p) | 2.2x6 | 4x4 | 4x4 | 4x4 | 5.5x4 | 5.5x4 | ||||

| Slide Adjust Device (HP) | Manual operation | |||||||||

| Air Pressure (kg/cm2) | 6 | 6 | 6 | 6 | 6 | 6 | ||||

| Presses Precision | GB(JIS)1 class | GB(JIS)1 class | GB(JIS)1 class | GB(JIS)1 class | GB(JIS)1 class | GB(JIS)1 class | ||||

| Presses Dimension (mm) | 1236x856x1920 | 1280x850x2200 | 1280x850x2200 | 1380x900x2400 | 1600x950x2500 | 1600x1000x2800 | ||||

| Presses Weight(Ton) | 1.8 | 2.1 | 2.1 | 3 | 3.8 | 5.6 | ||||

| Die Cushion Capacity(Ton) | - | - | - | 2.3 | 2.3 | 3.6 | ||||

| Die Cushion Stroke (mm) | - | - | - | 50 | 50 | 70 | ||||

| Die cushion effective area (mm2) | - | - | - | 300x230 | 300x230 | 350x300 | ||||

| C Frame Single Crank Press Machine | ||||||||||||

| APA-80 | APA-110 | APA-160 | APA-200 | APA-260 | APA-315 | APA-400 | ||||||

| V Type | H Type | V Type | H Type | V Type | H Type | V Type | H Type | V Type | H Type | V Type | H Type | V Type |

| 80 | 110 | 160 | 200 | 260 | 315 | 400 | ||||||

| 4 | 2 | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 8 | 4 | 8 |

| 35-80 | 80-120 | 30-60 | 60-90 | 20-50 | 40-70 | 20-50 | 50-70 | 20-40 | 40-50 | 20-40 | 40-50 | 20-35 |

| 65 | 50 | 35 | 35 | 30 | 30 | 30 | ||||||

| 150 | 70 | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | 250 | 150 | 300 |

| 340 | 380 | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 | 500 | 550 | 550 |

| 80 | 80 | 100 | 110 | 120 | 120 | 120 | ||||||

| 560x420x70 | 650x470x80 | 700x550x90 | 850x630x90 | 950x700x100 | 950x700x100 | 1050x840x95 | ||||||

| 1000x550x90 | 1150x600x110 | 1250x800x140 | 1400x820x160 | 1500x840x180 | 1500x840x200 | 1800x950x200 | ||||||

| 50 | 50 | 65 | 65 | 65 | 65 | 65 | ||||||

| 7.5x4 | 11x4 | 15x4 | 18.5x4 | 22x4 | 30x4 | 37x4 | ||||||

| Electric driving | ||||||||||||

| 6 | 6 | 6 | 6 | 6 | 6 | 6 | ||||||

| GB(JIS)1 class | GB(JIS)1 class | GB(JIS)1 class | GB(JIS)1 class | GB(JIS)1 class | GB(JIS)1 class | GB(JIS)1 class | ||||||

| 1800x1180x3000 | 1900x1300x3200 | 2300x1400x3800 | 2615x1690x4075 | 2780x1850x4470 | 2780x1850x4500 | 3250x2150x4600 | ||||||

| 6.5 | 9.6 | 16 | 23 | 32 | 35 | 38 | ||||||

| 3.6 | 6.3 | 10 | 14 | 14 | 14 | 14 | ||||||

| 70 | 80 | 80 | 100 | 100 | 100 | 100 | ||||||

| 450x310 | 500x350 | 650x420 | 710x480 | 810x480 | 810x480 | 810x480 | ||||||