Complete Coil Feed lines with decoiler straightener, servo feeder for Vent and Louver Stamping

Basic Paremeters of Complete Metal Stamping Line

Raw Material Type: Hot Roll Steel

Coil Width: 70-800 mm

Material Thickness: 0.6-6.0 mm

Yield Strength: ≤400N/mm2

Coil I.D : 475-520mm

Coil O.D : 1500mm

Max. loading weight: 8ton

Working Speed: 0-22m/min

Stamping Press: 315ton

Complete Coil Feed lines with decoiler straightener, servo feeder for Vent and Louver Stamping

The Complete Coil Feed lines with decoiler straightener, servo feeder is a fully automated system that is designed to produce high-quality Vent and Louver used in HVAC systems. A typical complete metal stamping line consists of several components, including a loading coil car, uncoiler, straightener, feeder, stamping press, scrap conveyor, and automatic stacking system. The process starts when the operator loads the metal coil onto the loading coil car or uncoiler, which then feeds the metal coil through the straightener and feeder to the stamping press.

Once the press receives the material, it performs the stamping, forming, cutting, or punching operation to create the desired shape. The scrap metal or any imperfections are discarded through the scrap conveyor, while the finished products are stacked on the automatic stacking system.

Main Machines Of Complete Metal Stamping lines

Decoiler Straightener with Coil Car

A coil car transfers the material coil onto the uncoiler machine.

The Decoiler Straightener is responsible for unrolling the sheet metal and flattening it before being feed into the next stage. It comes with various motors to control the feeding and unrolling speed, ensuring a smooth and constant feed.

Servo Feeder

The NC Servo Feeder is responsible for feeding the flattened sheet metal into the punching press, which is vital for punching out the desired shape or pattern. The feeder is equipped with adjustable pins to ensure that the metal sheet is fed into the press accurately.

This servo feeder can provide multi-stage feeding at different intervals, making it versatile and compatible with various manufacturing processes.

Loop Bridge

The Decoiler Straightener 2 in 1 Machine and the NC servo feeder are connected by a loop bridging structure, allowing for seamless transfer of materials from the Decoiler Straightener to the feeder. This loop bridge helps to guide the sheet metal from the decoiler straightener towards the NC servo feeder, ensuring that the material is loaded accurately and efficiently. The bridging structure is designed to enable the material to flow smoothly from one stage to the next, reducing downtime and avoiding production delays. This connection also helps to ensure that the material is feed into the NC servo feeder at the correct angle and feed rate, allowing for increased precision and consistency throughout the manufacturing process. Overall, the direct connection between the Decoiler Straightener 2 in 1 Machine and the NC servo feeder via the bridging structure is an essential feature that allows for the smooth and efficient production of high-quality metal products.

Stamping Press

The Precision stamping Press is a core part of the production line which is responsible for punching holes, shapes, or patterns on the metal sheets. It features high-speed hydraulic systems and advanced control software that allows for precise and fast punching while minimizing errors.

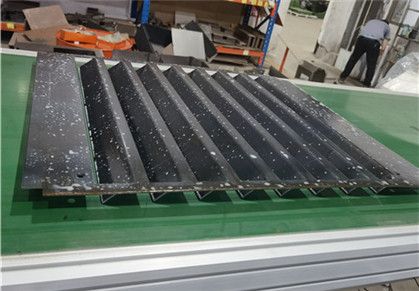

Pregressive Die

The Progressive Die is a critical component that allows for the creation of complex shapes and designs. It comprises multiple stages in which each step is completed in a separate station along the production line. The tooling is designed to ensure that each punch or cut is done precisely, resulting in consistent and high-quality finished products.

Vent Products Finished

Finally, the conveyor belt is responsible for transporting the finished Vent and Louver from the production line to the next stage in the manufacturing process.

In conclusion, the press feeding line for Vent and Louver Production Stamping is a state-of-the-art system that offers high productivity, cost-effectiveness, and flexibility in production. It is suitable for manufacturing Vent and Louver of various shapes, sizes, and materials, making it an ideal choice for HVAC companies looking to streamline their production operations.

SUNRUI Machine has always been committed to providing our clients with complete production line solutions. Our goal is to deliver the highest quality manufacturing equipment and expertise to help our customers optimize their processes and achieve their business objectives. Our team of experts is dedicated to understanding your unique needs and challenges, and we work closely with our clients to design, manufacture and install tailored manufacturing solutions that are customized to your specific requirements. With a focus on maximizing productivity, efficiency, and quality, we are committed to providing world-class products and services to our customers. If you have any needs for a complete production line, please do not hesitate to contact us. Our team is always ready to help and provide you with the best solutions.

Video of Complete Coil Feed lines with decoiler straightener, servo feeder