Boosting Output, Minimizing Downtime: How SUNRUI's Dual-Head Decoiler System Transformed Efficiency for a Roll Forming Leader

📈 Transformation Snapshot:

Coil Changeover Time: ⬇️ Reduced by 85%

Manual Threading Hazards: 🚫 Eliminated

Max Coil Handled Safely (No Crane): ⚙️ 4.5 Tons

Key Enabler: Integrated SUNRUI Dual-Head Decoiler & Coil Upender System

Customer Needs and Pain Points

As a premier roll forming specialist, our customer operated multiple lines with diverse and demanding requirements. Their manual processes and facility limitations created significant bottlenecks and risks:

Critical Facility Limitation: No Overhead Crane Available

The factory lacked overhead crane infrastructure, forcing all coil handling to rely solely on forklifts. This presented a major challenge: safely and efficiently loading heavy coils (up to 4.3 tons) from a horizontal forklift position onto the vertical mandrel of the decoiler. Manual methods were slow, risky, and required skilled operators to perform delicate and dangerous maneuvers.

Labor-Intensive & Hazardous Operation:

Without automated assistance, operators had to physically pull heavy, high-strength coil material by hand to thread the line, spinning the decoiler manually. This was not only inefficient but also posed serious safety risks from repetitive strain, pinching hazards, and potential handling accidents. The combination of manual threading and forklift-based loading doubled the safety and ergonomic concerns.Inconsistent Tension & Feed:

Reliance on manual toggle switches to activate/deactivate a basic pneumatic brake led to inconsistent material tension and feed, risking product quality variations and machine jams.Production Downtime:

The slow, forklift-dependent coil loading process, followed by manual threading and changeover, resulted in significant non-productive time, severely limiting overall equipment effectiveness (OEE).Handling Diverse & Demanding Materials:

Their production portfolio included a wide range of materials—from ultra-high-strength steel (766 MPa yield) to thicker, heavier coils (up to 4.3 tons)—across different widths and thicknesses. Their existing setup struggled with the precision and robustness required for such materials.Complex Integration Needs:

Some lines required precise synchronization with downstream equipment like loop storage pits, feeders, and presses. Others needed integration with laser sensors for automatic loop control. Their current setup lacked this sophisticated coordination.Lack of Automated Process Flow:

They urgently needed to automate the entire coil handling cycle: from receiving a coil via forklift, reorienting it, loading it onto the mandrel, rotating the turret, to clamping and threading—all with minimal operator intervention and maximum safety.

SUNRUI's Comprehensive, Line-by-Line Solutions

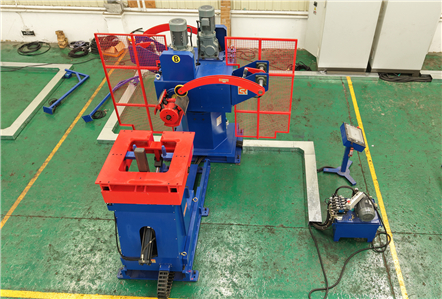

What is a Double Head Decoiler Machine?

A Double Head Decoiler Machine also called Dual head decoiler, Dual head uncoiler machine which is an advanced, automated coil handling system designed for continuous and efficient feeding of metal coils into roll forming or stamping production lines. It typically features two independent mandrels (heads) mounted on a rotating turret mechanism. While one mandrel actively feeds the coil into the processing line, the other mandrel can be loaded with the next coil, enabling a seamless, non-stop transition between coils—dramatically reducing downtime. This system automates critical processes such as coil loading, centering, clamping, threading, and tension control. It is the cornerstone of a modern, high-productivity, and safe roll forming operation, eliminating manual handling and ensuring consistent, high-speed material flow.

SUNRUI engineers conducted a thorough analysis of each roll forming line and provided bespoke solutions that addressed both the decoiling needs and the critical forklift-loading limitation.Integrated Solution:

Dual Head Decoiler + Coil Upender :To solve the "no crane" challenge, SUNRUI recommended and supplied Heavy-Duty Coil Upenders for key production lines.

This system creates a seamless, safe workflow:

Forklift Delivery: The forklift operator simply places the horizontal coil onto the lowered arms of the Coil Upender.

Automatic Reorientation: The Upender hydraulically rotates the coil 90° into a vertical position, perfectly aligned with the decoiler mandrel.

Integrated Transfer: The flipping table of the double head decoiler (or a separate transfer carriage) then moves in, receives the vertical coil, and transports it to the waiting mandrel for automatic loading and centering.

This eliminates all risky manual lifting and alignment, turning a two-person, high-skill task into a simple, one-forklift, automated operation.

| Line / Machine | SUNRUI Solution | Key Technical Parameters | Special Features & Integration |

|---|---|---|---|

| For Line 1 Roll Former | DBMT-200S + Coil Upender with Flipping Table | - Material Yield: Up to 766 MPa - Coil Specs: 73.5-119mm (W), 0.42-0.5mm (T), 1.6T, 508/1600mm (ID/OD) - Speed: 300m/min | - High-speed delivery for loop accumulator. - Upender enables safe, fast loading of 1.6T coils by forklift. |

| For Line 2 Roll Former | DBMT-200 + Coil Upender with Flipping Table | - Material Yield: 372 MPa - Coil Specs: 130-171mm (W), 0.5-0.55mm (T), 2.1T, 508/1600mm (ID/OD) - Speed: 120 m/min | - Upender solves heavy coil (2.1T) loading issue without a crane. |

| For Line 3 and Line 4 Roll Formers | DBMT-300 + Coil Upender with Flipping Table | - Material Yield: 354 MPa - Coil Specs: 125-248mm (W), 0.75-1.15mm (T), 3.1T, 508/1600mm (ID/OD) - Speed: 60 m/min | - Upender is essential for handling 3.1T coils safely. - Integrated loop/sync control. |

| For Line 5 Roll Former | DBMT-400 + Coil Upender with Flipping Table | - Material Yield: 630 MPa - Coil Specs: 144-351.5mm (W), 0.55-1.2mm (T), 4.5T, 508/1600mm (ID/OD) - Speed: 35 m/min | - Robust Upender designed specifically for the heaviest 4.5T coils, making forklift loading feasible and safe. |

Core Automation & Control Features (Applied Across All Solutions):

One-Touch Loading/Unloading: The flagship feature. A single command initiates the full automated cycle: Upender receives coil and rotates, flipping table transfers and loads coil onto mandrel.

Dual Control Modes: Full manual control for setup; seamless auto mode for production.

Intuitive HMI Interface: Displays real-time status of Decoiler, Flipping Table, and Coil Upender.

Automatic ID Centering: Ensures perfect alignment every time, compensating for variable coil OD.

Safety-Integrated Design: All motions pause if safety guards are opened, with resumable cycles.

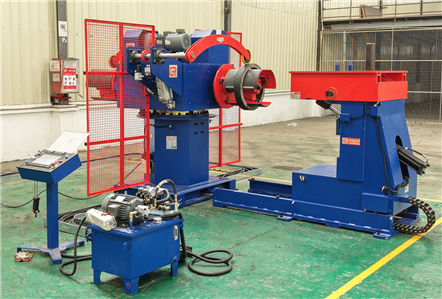

Dual Head Decoiler + Coil Upender

DBMT-300 + Coil Upender with Flipping Table

- Material Yield: Up to 354 MPa - Coil Width:0-300mm (W), - Coil Thickness: 0.3-2.0mm (T), - Coil Weight: 3.5T per side - Innder dimater and Outer diameter: 508mm/1600mm (ID/OD) - Speed: 60m/min

DBMT-400 + Coil Upender with Flipping Table

- Material Yield: Up to 630MPa - Coil Width:0-400mm (W), - Coil Thickness: 0.3-2.0mm (T), - Coil Weight: 4.5T per side - Innder dimater and Outer diameter: 508mm/1600mm (ID/OD) - Speed: 60m/min

DBMT-200S + Coil Upender with Flipping Table

- Material Yield: Up to 766 MPa - Coil Width: 0-200mm (W), - Coil Thickness: 0.3-2.0mm (T), - Coil Weight: 2T per side - Innder dimater and Outer diameter: 508mm/1600mm (ID/OD) - Speed: 300m/min

DBMT-200 + Coil Upender with Flipping Table

- Material Yield: Up to 372 MPa - Coil Width:0-200mm (W), - Coil Thickness: 0.3-2.0mm (T), - Coil Weight: 2.5T per side - Innder dimater and Outer diameter: 508mm/1600mm (ID/OD) - Speed: 120m/min

DBMT-300 + Coil Upender with Flipping Table

- Material Yield: Up to 354 MPa - Coil Width:0-300mm (W), - Coil Thickness: 0.3-2.0mm (T), - Coil Weight: 3.5T per side - Innder dimater and Outer diameter: 508mm/1600mm (ID/OD) - Speed: 60m/min

DBMT-400 + Coil Upender with Flipping Table

- Material Yield: Up to 630MPa - Coil Width:0-400mm (W), - Coil Thickness: 0.3-2.0mm (T), - Coil Weight: 4.5T per side - Innder dimater and Outer diameter: 508mm/1600mm (ID/OD) - Speed: 35m/min

Key Advantages of SUNRUI DBMT Series with Coil Upender System

Eliminates Crane Dependency: Provides a complete, safe coil handling solution for factories with only forklift access.

Unmatched Productivity: Drastically reduces coil loading and threading downtime. The Upender-Decoilergranted workflow enables changeovers in minutes instead of tens of minutes.

Superior Operator Safety: Removes personnel from all heavy lifting, hazardous manual handling, and precarious alignment tasks.

Exceptional Precision & Reliability: Engineered for heavy-duty performance, ensuring stable feeding of high-strength, heavy coils.

Seamless Integrated Workflow: The Upender and Decoiler are designed to work in perfect harmony, creating a single, automated material intake process.

Reduced Forklift Operation Time: Simplifies the forklift driver's task to a simple drop-and-go, freeing them for other duties.

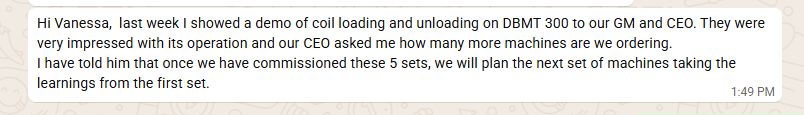

Client Acclaim and Our Invitation

The client was profoundly impressed with the complete SUNRUI solution. The integration of the Coil Upender with the Double Head Decoiler solved their fundamental infrastructure limitation. They reported a transformation in safety and efficiency: the dangerous, slow, and skill-dependent loading process was replaced by a simple, push-button operation. Downtime between coils was slashed, and operator fatigue was eliminated.

If your roll forming or stamping operations are constrained by manual decoiling, slow changeovers, lack of crane infrastructure, or unsafe coil handling practices, SUNRUI has the engineered, integrated solution. We specialize in creating tailor-made material handling systems that turn operational constraints into competitive advantages.

Contact SUNRUI today for a consultation. Let us design a solution that will have your team praising the results.

Double head decoiler with Coil upender video