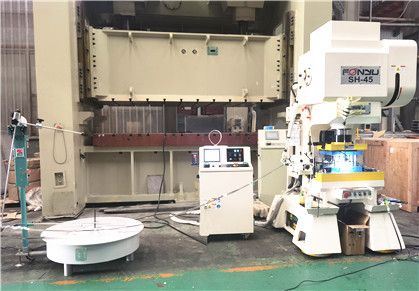

The OEM high-speed precision press line for aluminium long cup is working in military factory

Applicable material

Raw material: Aluminium

Material Thickness: 0.16mm

Coil width: 100mm

High Speed Precision Press Lines configuration

Pallet Decoiler FU-1000

High Speed Roll feeder RF-105NS

High Speed Press Machine RC/SH-45

Progressive Die for aluminium long cup

The OEM high-speed precision press line for aluminium long cup is working in military factory

A high-speed press line for aluminium long cup is a critical manufacturing process for military factories that require precision components for their equipment. Long cups are thin and small metal parts typically made of aluminum with a thickness of 0.16mm. The production process involves several stages to ensure consistency, efficiency, and precision.

The process starts with coil loading, where the raw material, aluminum coil, is loaded onto the machine. The aluminum coils are then feed into the flat decoiler, where they are unrolled and then fed into the high speed feeder, which moves the material forward to the stamping operation.

The stamping operation is where the magic happens. The high-speed press uses a ram to stamp out the cups from the aluminum strips. The cups are punched, formed, and then cut out of the strip in rapid succession. The process runs at high speeds 200SPM, allowing for a consistent and efficient production rate. After the stamping operation is complete, the finished cups are falling into the receiving box .The final product is then checked for quality and accuracy before being packaged for shipment.

The high-speed press line for aluminium long cup is a crucial manufacturing process for military factories that require precision components. The process ensures that the final product is accurate, consistent, and efficient. The finished long cups are used as essential components for various military products, which highlights the importance of the high-speed press line for long cup in military production.

Main Machine of High speed-precision press line

Pallet Decoiler Machine FU-1000

The pallet decoiler machine manufactured by SUNRUI-machine is a decoieler machine that is specifically designed to unroll metal coils from pallets.

The pallet decoiler machine also includes a decoiling speed adjustment mechanism, which enables operators to control the speed of the unrolling process, ensuring safe and precise operations.

The pallet decoiler machine is a valuable investment that offers a high level of efficiency and productivity for handling and unrolling metal coils from pallets.

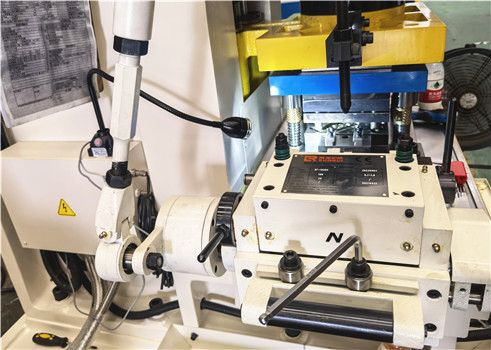

High speed roll feeder machine RF-105NS

A high-speed roll feeder machine is a type of equipment used in metal stamping processes to feed metal coils through a stamping press at high speeds.

It is specifically designed to process large volumes of continuous strip material quickly and efficiently. The machine is equipped with a set of feed rollers that pull the coil through the machine that removes any bends or kinks in the strip.

The high-speed roll feeder machine also includes a control system that regulates the speed and feeding length of the strips. This helps to ensure accuracy and consistency during the stamping process. High-speed roll feeder machines are commonly used in metalworking industries such as metal button, eyelets, long cup, terminal, where high production rates and precision are critical.

High speed press machine, SH-45

A high-speed press machine is a mechanical equipment used in metal stamping and forming processes that can operate at extremely high speeds. It is specifically designed to produce high volumes of stamped metal parts in a short amount of time.

The high-speed press machine consists of a vertical frame, a motor that drives the flywheel and a clutch/brake, a ram (or slide) which moves up-and-down, and a tool set that is mounted on the ram to perform the stamping and forming operations. The machine makes use of dies, which are molds that are used to form metal sheets into specific shapes.

The high-speed press machine is capable of operating at speeds of up to 1000 strokes per minute, making it one of the fastest stamping machines available in the market. This high-speed capability makes it ideal for use in high-volume production environments, such as the precision products industries.

The high-speed press machine can produce metal parts with a high degree of accuracy and consistency, which is important because even small variations in stamping can cause defects in the final product. The machine can also perform a variety of metal forming processes, including blanking, piercing, and bending, making it a versatile tool in metalworking.

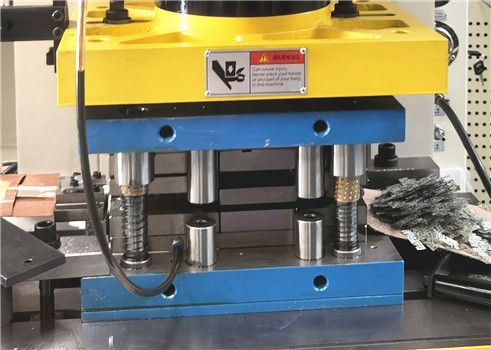

Progressive die

A progressive die is a type of metal stamping die used in high-volume manufacturing processes for producing stamped metal parts with complex shapes. It is designed to perform a sequence of stamping operations on a metal strip progressively, while the strip advances through the machine. The die is typically composed of multiple stations, with each station performing a specific stamping operation on the metal strip.

The progressive die works by cutting and shaping the metal strip in stages, using a series of punches and dies that are mounted in the die set. The first station of the die performs the first stamping operation on the strip, while the second station performs the second operation, and so on, until the final product is complete.

The progressive die allows for the production of complex, high-quality metal parts with high accuracy and consistency. It is commonly used in industries such as automotive, electronics, and appliances, where large quantities of metal parts with complex shapes are required.

The progressive die is a valuable tool in metalworking because it significantly reduces the time and cost associated with producing stamped metal parts. Because the die performs multiple stamping operations at once, the process is more efficient, leading to increased productivity and lower production costs.

Aluminium long cups

Usuauly, this kinds of durable and high-quality aluminum long cups can be a daunting challenge for businesses. Many of these cups are prone to deformation and easily break, posing a challenge for the stamping industry and a test of our technical expertise.

Combines with our high precision stamping machines that we have overcome this challenge and have developed long cups that offer unmatched durability and resilience. Our cups undergo rigorous testing to meet our customer's high precision requirements and exceed their expectations.

Video of high-speed precision press line for aluminium long cup