Press Feed Line MFL5-800 for the Electronics Industry

MODEL: MFL5-800

Raw Material Type: High tension strength Hot-Rolled Metal steel, Cold-Rolled Metal steel ,Stainless Steel etc.

Coil Width: 70-800 mm

Material Thickness: 1.0-8.0 mm

Yield Strength: ≤630 N/mm2

Coil I.D : 475-520mm

Coil O.D : 1500mm

Max. loading weight: 10ton

Working Speed: 0-22m/min

A reliable and high-quality Press Feeding Line supplier for your Electronics industry

SUNRUI recommended a press feed line with the following components:

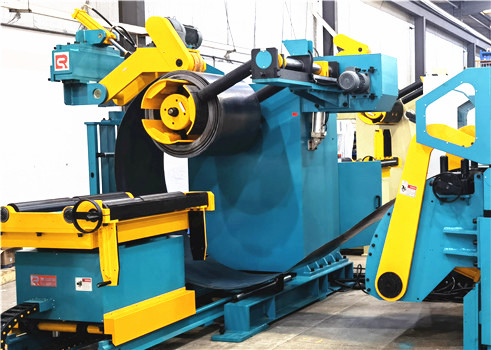

1. Uncoiler

The uncoiler facilitates the feeding of the material from the coil to the rest of the press feed line. For this client, the uncoiler provided the following benefits:

- High-speed capabilities for fast coil changeovers, minimizing downtime

- Automatic speed adjustment to synchronize with the rest of the press feed line, increasing process efficiency

- Laser-guided loop control system for accurate material feeding and reduced scrap rates

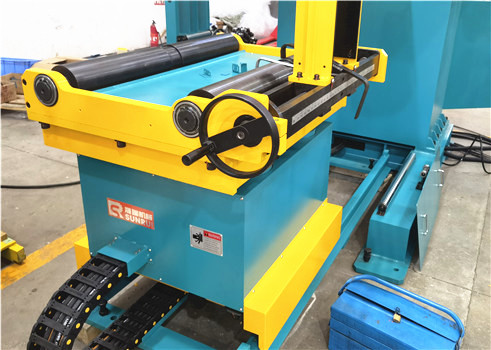

2. Straightener

The straightener ensures that the material is flat and free from any curves or wrinkles. For this client, the straightener provided the following benefits:

- High-performance straightening rolls and pinch rolls for stable and precise material feeding

- Crosshead adjustment system for easy and accurate setup, reducing setup time between runs

- Automatic material guiding system for consistent feeding, minimizing scrap rates

3. Servo Roll Feeder

The servo roll feeder feeds the material into the die to perform the stamping operation. For this client, the servo roll feeder provided the following benefits:

- High-precision feeding for accurate stamping results and reduced scrap rates

- Fast-response servo motor for greater control and flexibility in feeding speed and distance

- Digital control system for easy setup and adjustment, and to store multiple feeding programs for different stamping requirements.

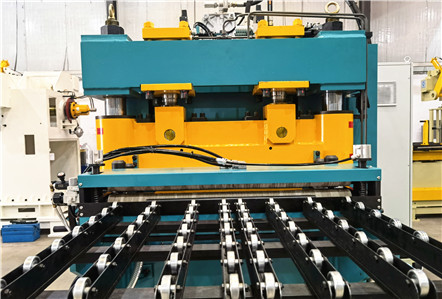

4. Hydraulic shear machine

The hydraulic shearing machine cuts the material's head and tail with ease. It utilizes hydraulic power to provide a precise and efficient cutting mechanism, making it an ideal choice for various metal processing industries. The system's advanced design allows it to shear through a range of materials with different thicknesses, providing high-quality cuts that meet industry standards.

The hydraulic shearing machine offers many benefits, including a high level of precision, low noise output, and low energy consumption. It's user-friendly and safe operation also makes it a popular choice for metalworking operations that require accurate cutting.

5. Electrical control system

The press feed line's electrical control system incorporates top-of-the-line components from leading manufacturers, such as Yaskawa servo systems from Japan and Mitsubishi human-machine interface (HMI) technology.

The Yaskawa servo systems are renowned for their exceptional performance and reliability in industrial automation. The servo motors and drives in the press feed line's electrical control system enable precise and dynamic control of the uncoiler, straightener, and servo roll feeder. This allows for high-precision material feeding and stamping, ultimately producing high-quality finished products.

On the other hand, the Mitsubishi HMI technology is designed to provide intuitive and efficient control over the press feed line. The HMI displays real-time data from the press feed line and provides access to various system settings, enabling operators to monitor and adjust the performance of the system with ease. The user-friendly interface reduces the need for specialized training and ensures that operators can quickly and accurately modify the press feed line's settings to meet specific requirements.

Together, the Yaskawa servo systems and Mitsubishi HMI technology optimize the performance of the press feed line, enhancing productivity, quality, and efficiency across the production process. At SUNRUI, we understand the importance of a well-designed and integrated electrical control system and only use the best components to deliver outstanding results for our clients in various industries.

By implementing a press feed line with these components, the manufacturer in the electronics industry was able to optimize their stamping process, resulting in increased production output and improved product quality. Moreover, the reduced scrap rates contributed to significant cost savings, enabling the client to stay competitive in their market.

In conclusion, a press feed line with an uncoiler, straightener, and servo roll feeder can provide a range of benefits for the electronics industry, including high-speed capabilities, precise material feeding, and reduced scrap rates. At SUNRUI, we are committed to providing our clients with the best solutions to meet their unique needs and challenges. Contact us today to learn more about our press feed line solutions and how we can help you optimize your stamping process.

Press Feeding Line Testing video