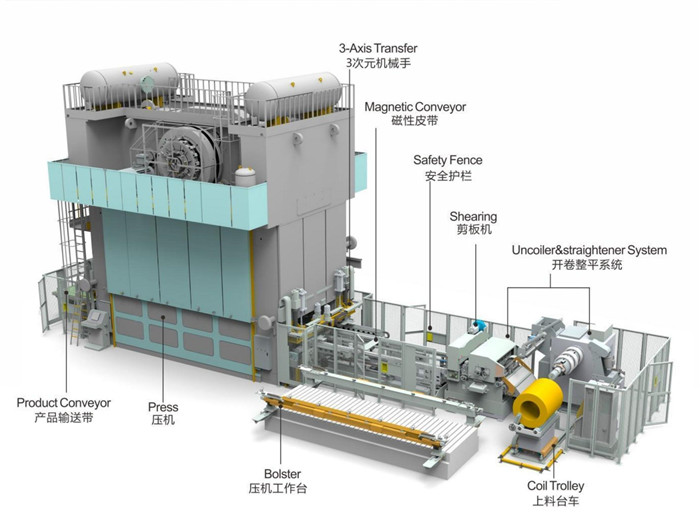

3 Axis Transfer System With Coil Feed Line

SUNRUI fully automatic 3-axis transfer stamping line is an efficient manufacturing system that consists of the following main components:

Compact coil feed line

Hydraulic shearing machine

Magnetic conveyor or conveyor

3-axis transfer system

Stamping press machine

Product end conveyor

Brief Profile of 3 Axis Transfer System With Coil Feed Line

The SUNRUI 3-axis transfer system with coil feed line is a specific type of manufacturing system designed for high-volume production of stamped metal parts. It combines a 3-axis transfer system with a coil feed line to automate the production process.

The 3-axis transfer system consists of robotic arms or transfer mechanisms that can move in three directions (x, y, and z). These arms are responsible for transferring the workpiece between different stations in a precise and efficient manner. The transfer system ensures accurate positioning and timing during the manufacturing process.

The coil feed line, on the other hand, is responsible for feeding the metal coil into the line. It typically includes a decoiler, straightener, and feeder. The decoiler unwinds the metal coil, the straightener removes any coil-set or curl, and the feeder feeds the metal strip into the line. The coil feed line prepares the metal strip for further operations, such as cutting, forming, or stamping.

By combining the 3-axis transfer system with the coil feed line, the SUNRUI system offers a seamless and automated production process. The transfer system handles the movement of the workpiece between different stations, while the coil feed line ensures a continuous supply of metal strip for processing. This integration improves production efficiency, reduces manual labor, and maintains consistent quality throughout the manufacturing process.

Overall, the SUNRUI 3-axis transfer system with coil feed line is a comprehensive solution that combines advanced transfer technology with efficient coil feeding, enabling high-speed and high-precision production of stamped metal parts.

The Features of 3 Axis Transfer System With Coil Feed Line

SUNRUI 3-axis transfer system with a coil feed line combines advanced features to provide a versatile and efficient solution for high-volume production. This system offers several key features that enhance productivity and ensure precision throughout the manufacturing process.

Versatility is a significant advantage of the 3-axis transfer system. Its multidirectional movement capability allows for flexible feeding and transferring of the coil to different processing stations or machines. This versatility enables the efficient production of complex parts or components.

Precision is another important feature of the transfer system. Equipped with high-precision servo motors or other advanced control systems, the system ensures accurate positioning and movement of the material. This precision helps maintain consistent quality and dimensional accuracy in the produced parts.Integration is seamless between the transfer system and the coil feed line. This integration allows for smooth and continuous material feeding, straightening, and transferring operations. By minimizing downtime, the integrated system maximizes productivity.

Automation is a significant advantage of the transfer system. It is fully automated, reducing the need for manual intervention and improving overall production efficiency. Automated features may include coil loading and unloading, part ejection, and tool changeovers.

Control and monitoring are essential aspects of the system. Advanced control panels and software interfaces allow operators to easily program and monitor the system. Real-time monitoring helps identify and address any issues or deviations during the production process.Safety features are incorporated into the transfer system to ensure operator safety and prevent accidents. Sensors, emergency stop buttons, and protective barriers are implemented to mitigate any potential risks.

Customization options are available for tailoring the transfer system to specific production needs. Adjustable feed rates, programmable parameters, and various tooling options can be customized as per the requirements of the manufacturing process.In conclusion, a 3-axis transfer system with a coil feed line offers versatility, precision, automation, integration, and customization capabilities. This efficient and reliable solution is ideal for high-volume production, enabling manufacturers to achieve optimal productivity and maintain consistent quality in their manufacturing operations

Main Parts of 3 Axis Transfer System With Coil Feed Line

SUNRUI fully automatic 3-axis transfer stamping line is an efficient manufacturing system that consists of the following main components: a compact coil feed line, shearing machine, magnetic conveyor or conveyor, 3-axis transfer system, stamping press machine, and product end conveyor.

Here is a detailed overview of the entire production line process:

Compact coil feed line

The process begins with the metal coil being unwound from the decoiler. The straightener removes any coil-set or curl from the metal strip. Then, the feeder transports the metal strip to the next station.

Shearing machine

The metal strip enters the shearing machine, where it is cut to the desired length or size. This ensures precise cutting before the stamping process.

Magnetic conveyor

After shearing, the metal strip is transferred using the magnetic conveyor. This conveyor utilizes magnetic force to ensure smooth and accurate transfer of the workpiece along the line.

3-axis transfer system

The metal strip is then transferred to the 3-axis transfer system from the magnetic conveyor. This system consists of robotic arms or transfer mechanisms that can move in three directions (x, y, and z). It precisely transfers the workpiece from one station to another, ensuring high accuracy and efficiency.

Stamping press machine

After the transfer system, the metal strip enters the stamping press machine. This machine utilizes dies and punches to shape or form the metal strip into the desired parts. By applying pressure, the machine creates the required shapes, holes, or patterns.

Product end conveyor

Once the stamping is completed, the finished stamped parts are collected and transferred to the next manufacturing stage or packaging area using the product end conveyor. This conveyor ensures proper handling and transportation of the completed parts.

Through this process, our fully automatic 3-axis transfer stamping line enables efficient, high-speed, and high-precision production of metal parts. The coordinated operation of each component ensures automation, continuity, and consistent quality throughout the production process. This production line significantly improves productivity, reduces manual labor, and maintains consistent product quality.

3 Axis Transfer System With Coil Feed Line Video