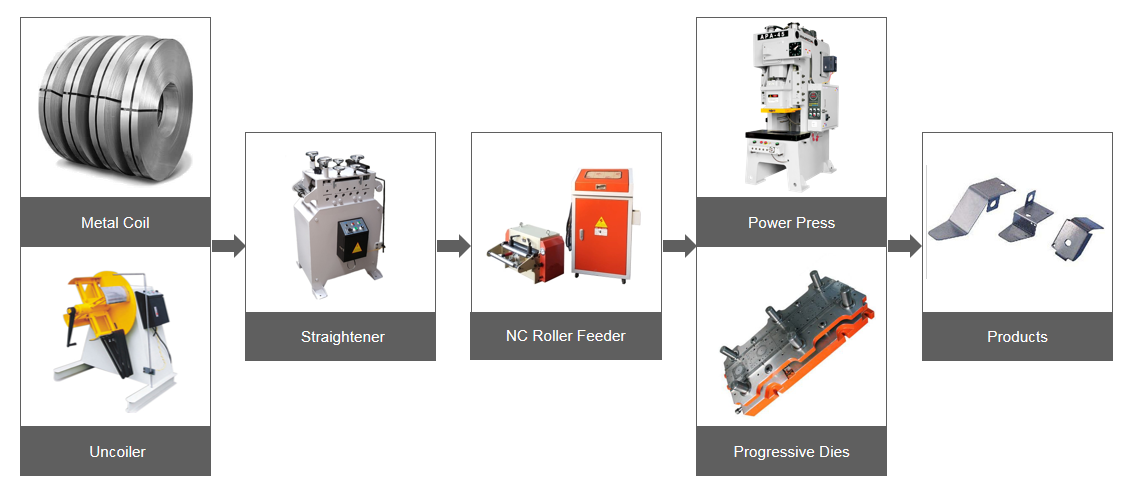

Simple Press Stamping Line

Applicable material

Material Thickness: 0.1-2.0m

Coil width: 20-300mm

Coil line configuration

Decoiler Machine MT/MT-F

Coil straightener machine (For optional) TL/SNL/STL

Coil feeder RNC/NCF/RF

Progressive(For optional)

Unwinder machine MT/MT-F(For optional)

Simple Press Stamping Line

The configuration of Press Stamping Line.

Step-1: Decoiler machine, Loading coil and uncoilling coil.

Step-2: Straightener machine, leveling the coil strip.

Step-3: Coil Servo Feeder machine, Feed coil strips to press machine.

Step-4: Stamping press machine with the progressive die, pressing to the end product.

Main Machine

Decoiler Machine MT/MT-F

Decoiler power: Moterized

Uncoiling expansion:Manual

Pressure Arm: Pneumatic type, no moterized PU wheel

Coil inner dimater: 508mm

Coil outer diamter: 1200mm

Max. loading weight: 1500kgs

Straightener machine TL/SNL/STL

Coil width: 300mm

Coil thickness: 0.1-2.0mm

Straightener machine is equipped according to the thickness and requirements about the leveling precesion.

If the thickness range 0.1-0.6mm, then choose the SNL or STL high precision straightener machine, if the thickness is 0.4-2.0mm, then choose the TL straightener machine.

Coil feeder RNC/NCF/RF

Coil width: 300mm

Coil thickness: 0.1-2.0mm

Speed:20m/min

Sunrui coil feeder machine is reliable choice for metal sheet stamping process, it can meet various type coil feedling requirements.

According to different requirements, servo feeder with pnumatic release and mechanical release can be optional.

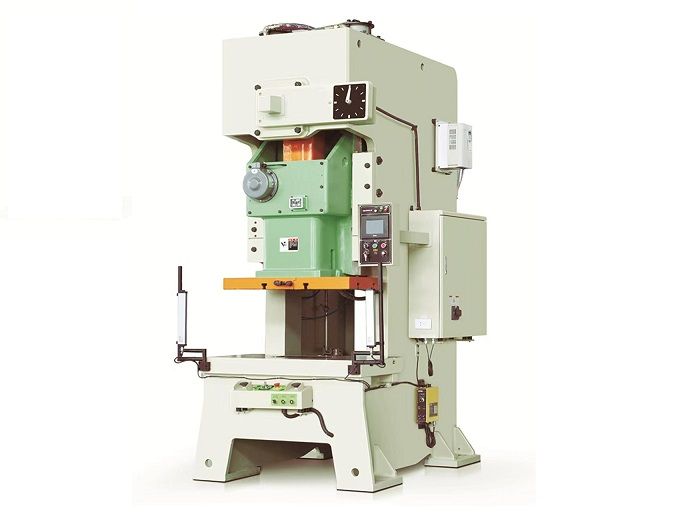

Mechanical Press Machine APA(15-200ton)

Type: Pnematic or mechanical press machine

Tonnage capacity: 15-200ton

Steel welded body, tempering treatment, high rigidity, accuracy and stability, low integrated clearance, small changing in mold height.

Small deviation of dynamic center, the mold life in large scale, small transfiguration for press.

Vertical located crankshaft, compact structure.

The crankshaft undergoes grinding treatment after high frequency quenching.

Progressive Die

Progressive die stamping is a process used during metal forming that can create parts for a host of industries. Progressive dies are often utilized in higher-volume production, with their components engineered to function at higher rates of speed.

Customized according to client's drawing of parts.

Unwinder Machine MT/MT-F

Unwinder power: Moterized

Recoiling expansion:Manual

Pressure Arm: Pneumatic type, no moterized PU wheel

Coil inner dimater: 508mm

Coil outer diamter: 1200mm

Max. loading weight: 1500kgs

It's used to recoil the coil sraps or coil strips.