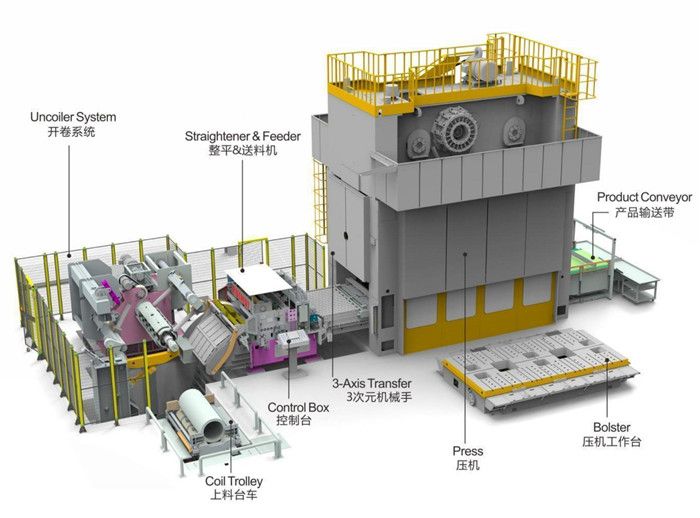

Coil feed line with Press Transfer System for Auto stamping line

SUNRUI Coil feed line with Press Transfer System for High strength continuous stamping line is an efficient manufacturing system that consists of the following main components:

Compact coil feed line

3-axis transfer system

Stamping press machine

Product end conveyor

Brief Profile of Coil feed line with Press Transfer System

SUNRUI coil feed line with press transfer system for high strength continuous stamping line is a system used in the manufacturing industry for the efficient and automated feeding of metal coils into a stamping press.

This system is specifically designed to handle high-strength materials, such as advanced high-strength steels, which are commonly used in automotive and other industries where strength and durability are critical and this integrated system allows for a continuous and automated stamping process, minimizing downtime and maximizing productivity. It also ensures accurate and consistent feeding of high-strength materials, which can be challenging due to their inherent stiffness and strength.

The system consists of several components:

Compact coil feed line

This is a compact and automated system that is used to feed coils of material, such as steel or aluminum, into the stamping press machine. It typically includes a coil reel, straightener, and feeder, which work together to accurately feed the material into the press.

3D transfer system

This is a specialized transfer system that moves the stamped parts from one station to another within the stamping press machine. It allows for precise positioning and movement of the parts, ensuring consistent and accurate stamping operations.

Stamping press machine

This is the main machine in the line, which applies force to the material to shape it into the desired form. It usually consists of a press bed, slide, and die, and is capable of high-strength stamping operations.

Product end conveyor

This is a conveyor system that transports the finished stamped parts from the press to the next stage in the production line or to a storage area. It ensures smooth and efficient flow of the parts, reducing downtime and increasing productivity.

Overall, the Coil feed line with Press Transfer System for High strength continuous stamping line is a comprehensive system that combines the coil feeding, stamping, and part transfer processes into a seamless and efficient production line. It is designed for high-strength stamping operations, where precision and accuracy are crucial.

The Features of Coil feed line with Press Transfer System

SUNRUI Coil feed line with Press Transfer System for High strength continuous stamping line offers several features that enhance its efficiency and productivity.

Compact design

The system is designed to take up minimal floor space, ensuring efficient use of available space in the manufacturing facility.

Automation

The system is highly automated, reducing the need for manual intervention and increasing the speed and accuracy of the stamping process. High-speed operation: The system is capable of high-speed feeding and transferring of coils and stamped parts, allowing for increased production rates.

Precise material feeding

The compact coil feed line ensures accurate and consistent feeding of coils into the stamping press machine, minimizing material waste and improving overall quality. 3D transfer system allows for precise positioning and movement of stamped parts within the press, ensuring accurate and repeatable stamping operations.

Quick die change system

The system may include a quick die change feature, allowing for efficient and rapid changeover of dies, reducing downtime and increasing productivity.

Integration with product end conveyor

The product end conveyor seamlessly connects the stamping press machine to the next stage in the production line, ensuring smooth and efficient flow of finished parts.

Safety features

The system is equipped with safety measures to protect operators and prevent accidents, such as safety guards, emergency stop buttons, and sensors.

Overall, the features of the Coil feed line with Press Transfer System for High strength continuous stamping line are designed to optimize productivity, accuracy, and safety in the stamping process.