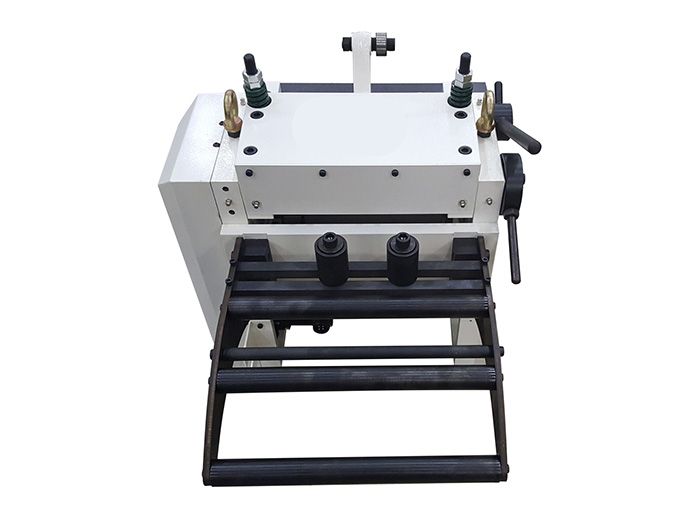

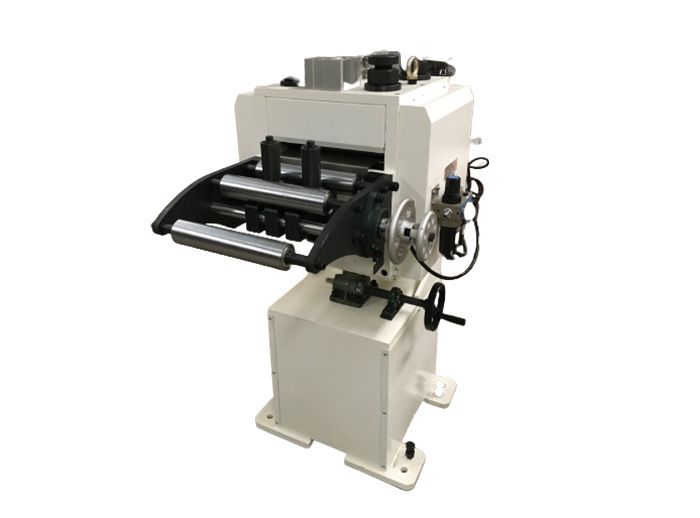

Feeder

A coil feeder machine is a type of equipment that is used to feed metal coils into a stamping or press machine. It is designed to automatically feed the coil material into the machine, ensuring a consistent and accurate feeding process. The coil feeders come equipped with features such as servo-driven motors and advanced control systems, which help to provide accurate feeding and speed control. Coil feeder machines can handle a variety of coil materials such as steel, aluminum, and copper in various thicknesses and widths. They are commonly used in industries such as automotive, aviation, electronics, and appliances.

According to the different feeding power, the feeder machine can be divided into 3 types which is mechanical type, hydraulic type and pneumatic type feeder machine. In the stamping process, mechanical and pneumatic type feeder machine is very popular and common.

The pneumatic feeder machine has the advantages of being smart and light, versatile, adjustable in feeding length and material thickness, and quick in response of the mechanism.

However, since the pneumatic feeder machine works by the differential pressure pneumatic principle, the working noise of the mechanism is large! It affects the working environment of the stamping! It is mainly used for pre-feeding of stamping and production of small batches and varieties.

Although the mechanical feeder machine is relatively difficult to adjust and the mechanism is large, it has the advantages of accurate and reliable feeding, less impact and vibration of the mechanism, low noise, good stability, etc. It is still the most commonly used automatic feeding method in the current stamping processing.

At present, the application of the stamping production line is widely used in the open single-point press with a roller feeder. This production line can be continuously stamped in a single process or in multiple processes, and has good operability.Another open double-point press is equipped with a multi-station feeding device, which is equipped with a winding machine, a leveling device, etc., which is used for multi-station continuous stamping. The floor space and handling between processes are significantly reduced. Applications in production are showing an increasing trend.

The production line of the special-purpose motor silicon steel sheet for the motor plant is composed of a high-speed press equipped with a cam split type feeder, equipped with an unwinder and a leveling device.

It can be seen that the performance of the feeding mechanism directly affects the promotion and application of the production line. Therefore, it is necessary to select different feeding mechanisms for the process requirements of the stamped parts and the actual production conditions.

Sunrui Machinery is a supplier of servo feeders, which are essential equipment in the manufacturing industry for accurate and efficient feeding of materials. If you are looking to buy a servo feeder, Sunrui Machinery offers a range of high-quality products to meet your needs.

When it comes to price, the cost of a servo feeder can vary depending on the specific model, capacity, and features. If you are interested in purchasing a servo feeder from Sunrui Machinery, you can request a quote directly from the website. Simply provide your contact information and specifications, and our sales team will provide you with a customized quote.