Straightener Machine STL (0.1-0.6mm)

Applicable Material

Suitable for vary kind of coil material, such as Galvanized steel, Stainless steel, CR Steel, HR Steel, Galvanized steel, Stainless steel, Aluminum, Cooper etc.

Applications: Pressing Line/Metal Stamping Line

Applicable Coil Width: 20mm-300mm

Applicable Coil Thickness: 0.1-0.6mm

Speed: 15m/min

Applications: Pressing Line/Metal Stamping Line

Brief Profile of Straightener Machine

The precision straightener machine operates by feeding the metal sheet or strip through a series of rollers that apply pressure and force to flatten the material.

Straightener machines typically consist of two sections: a rough straightener section and a precision straightener section. The rough straightener section has larger rollers that perform the initial straightening process. The precision straightener section has smaller rollers that refine the straightening process, improving the precision and accuracy of the flattened material.

The precision straightener machine offers several advantages over conventional straightening machines, including:

1. High precision: The precision straightener machine is capable of achieving high levels of accuracy and precision, making it ideal for stamping operations that require tight tolerances.

2. Dual-end straightening: The machine performs straightening on both ends of the material, ensuring that the entire length of the sheet or strip is flat and even.

3. Flexible operation: The machine can handle a range of materials and thicknesses, making it a versatile machine for use in stamping operations.

4. Consistent results: The precision straightener machine delivers consistent and reliable results, ensuring that each sheet or strip is straightened to a high degree of accuracy and quality.

In summary, the precision straightener machine is an advanced industrial machine used to straighten and flatten metal sheets or strips to precise tolerances. It can be found in stamping operations for numerous applications that require high precision and accuracy.

Application of Straightener Machine

Application scenario of high-precision straightening machine:

Metal Coil Processing: High-precision straightening machines are extensively used in industries that deal with metal coils, such as steel mills, metal service centers, and coil processing facilities. These machines can straighten coils of different materials, including steel, aluminum, copper, and stainless steel. The straightened coils are then used for further processing, such as cutting, stamping, or forming.

Automotive Industry: In the automotive sector, high-precision straightening machines are utilized to straighten coils of metal sheets or strips, which are commonly used for manufacturing car body parts. The machine ensures that the coils are flattened and straightened, removing any distortions or unevenness. This results in high-quality metal sheets that can be seamlessly formed into car components.

Appliance Manufacturing: Straightening machines find application in the production of appliances such as refrigerators, washing machines, and air conditioners. Metal coils used in these appliances, like condenser coils or evaporator coils, need to be straightened before they can be assembled into the final product. The straightening machine ensures that the coils are perfectly aligned, facilitating efficient assembly and optimal performance of the appliances.

Construction and Infrastructure: High-precision straightening machines are used in the construction industry for straightening metal coils used in structural elements like beams, columns, and profiles. Straightened metal coils ensure that the structural components are accurately aligned and have the required dimensional stability, enabling safe and reliable construction.

Electrical and Electronics: In the electrical and electronics industry, straightening machines are employed to straighten metal coils used in the production of transformers, electric motors, and generators. STL high-precision straightener machines can be found in mobile phone accessories stamping, PC accessories stamping and many other digital parts stamping. A precision straightener machine has excellent straightener performance for electrical components stamping. Straight coils help in maintaining precise air gaps, reducing energy losses and improving the efficiency of these electrical devices.

Metal Recycling: Straightening machines play a crucial role in metal recycling facilities. They are used to straighten coils of metal scrap, such as shredded cars or appliances, before further processing. Straightened metal coils are easier to handle and feed into shredders, melting furnaces, or other recycling equipment.

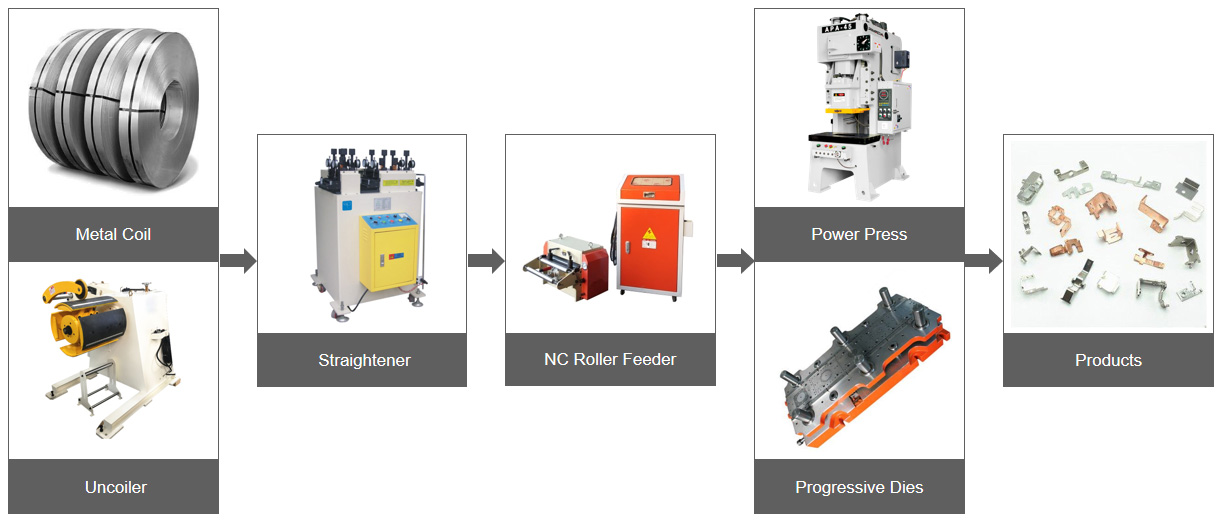

The configuration of metal sheet stamping line.

Step-1: Uncoiler machine, Loading coil and uncoilling coils

Step-2: High precision straightener machine, leveling the strips and lead it to feeder machine.

Step-3: Nc Servo Feeder machine, Feed coil to press machine.

Step-4: Power press machine with the moulds,pressing to the end product.

Feature of Straightener Machine

● This type is suitable for material thickness: 0.1-0.6mm.

● Suitable for all kinds of metal coil automatic straightening ,easy to operate.

● Suitable for metal parts, electron, electrical appliance, toy and auto parts continuous pressing production, straightening.

● The rectifying roller is made of solid bearing steel, which is grinding and plated with hard chromium after high frequency heat treatment.

● It adopts some universal joints as independent transmission, instead of gear transmission, so can get better straightening performance.

● It has an electronic sensor for automatic loop control.

● An inverter is equipped in order to adjust variable decoiling speed easily.

● It has two operation modes, as manual mode and automatic mode. It can feed the metal sheet forward or reverse under manual model, in order to check trial straightening performance. After testing well, user can turn to automatic mode to work with feeder or another machine synchronously.

● High rigidity mechanical structure, high horsepower output. High speed and stable feeding can be made to improve the production efficiency and prolong the service life of the equipment.

● The machine can be used independently, and it can be used together with MT and DBMT automatic feeder, with better effect.

Specification of Straightener Machine

| Model | STL-150 | STL-200 | STL-300 |

| Max. Width (mm) | 150mm | 200mm | 300mm |

| Thickness(mm) | 0.1-0.6 | ||

| Straightener roller | First group Φ20*6pcs 3/3 (up/down) | ||

| Second group Φ20*19pcs 9/10 (up/down) | |||

| Speed | 0-16m/min | ||

| Motor | 0.5HP | 1HP | 1HP |

| Voltage | AC220V/ AC415V | ||

| machine Weight | 180KG | 200KG | 280KG |