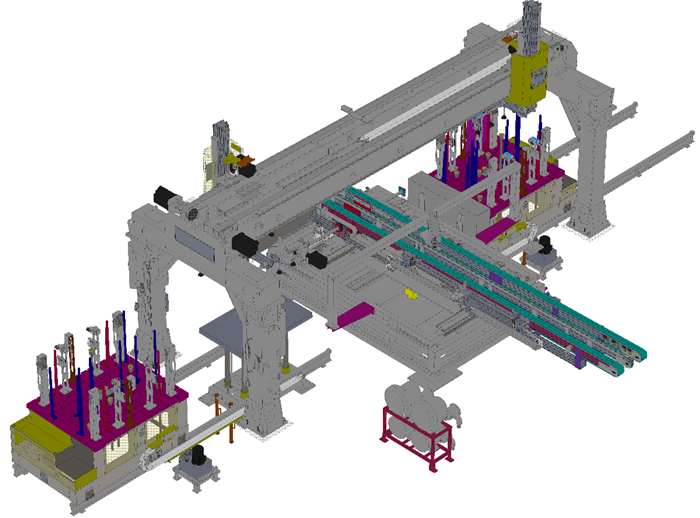

Destacker / Destacking System

SUNRUI destacking equipment is engineered to cater to diverse applications and requirements. Whether you need a pallet destacker, stack destacker, or any other specialized solution, our versatile system can be tailored to your specific needs.We are a trusted manufacturer of destacker systems. Our cutting-edge technology, combined with our expertise in material handling, ensures superior performance and longevity. We offer comprehensive destacking solutions that streamline your operations, improve workflow, and boost your bottom line.

Brief of the Destacker

In industrial applications, a destacker is a machine that automates the process of separating and feeding individual sheets, products, or components from a stack. It is an essential component of many production lines where a high volume of materials needs to be processed.

The destacker typically consists of a robust frame or structure that supports the stack of items to be destacked. The stack is usually loaded onto a tray, pallet, or feeder platform, which can be manually or automatically loaded onto the destacker.The destacking process involves lifting and separating the topmost item from the stack and then transferring it to a downstream process or conveyance system. This separation can be achieved through various methods, depending on the type of materials being handled.

Mechanical destackers use mechanisms like grippers, clamps, or suction cups to hold and lift the topmost item from the stack. These mechanisms are usually adjustable to accommodate different sizes and shapes of materials.

Pneumatic destackers utilize air pressure to lift and separate the top item. They employ pneumatic cylinders or vacuum systems to create the required force to lift the materials.

Vacuum destackers are particularly useful for handling thin or delicate items like metal sheets or electronic components.Once the top item is lifted, it is transferred to the next stage of the production process. This can be a conveyor belt, a robotic arm, or a specialized system for further assembly, packaging, or processing.

Destackers offer several benefits to industrial processes. They increase productivity by automating the separation and feeding of materials, reducing the need for manual labor. They also ensure a consistent and continuous flow of materials, minimizing downtime and improving overall efficiency. Additionally, destackers help prevent damage to delicate or sensitive items during the destacking process.Overall, destackers play a crucial role in streamlining production lines, improving efficiency, and reducing costs in various industries that deal with stacks of materials

Destacker System General Specifications

The Destacker System is a versatile and efficient solution for material handling in various industrial applications. Designed to optimize productivity and minimize time loss, it offers a range of features and specifications that make it a valuable asset in any manufacturing setting.

Working Speed up to 25spm

The Destacker System is capable of operating at high speeds of up to 30 strokes per minute. This ensures a rapid and continuous flow of materials, enhancing overall productivity and reducing production time.

Magnetic and Non-Magnetic Material Working Ability:

The system is specifically designed to handle both magnetic and non-magnetic materials with equal efficiency. This versatility allows for greater flexibility in material selection and eliminates the need for separate systems for different material types.

Automatic Station Change

To prevent time loss during material load, the Destacker System incorporates an automatic station change feature. This allows for seamless transitions between loading stations, ensuring a smooth and uninterrupted workflow. Loading Station positions as parallel or transverse direction to flow direction: The loading stations can be positioned either parallel or transverse to the flow direction, providing flexibility in material handling. This adaptability allows for efficient loading and unloading of materials from different angles, accommodating various production requirements.

Easy and fast vacuum set change with Quick Change cartesian unit

The Destacker System incorporates a Quick Change cartesian unit, enabling easy and fast vacuum set changes. This feature streamlines the setup process, minimizing downtime and maximizing productivity. Double sheet control on each unit for both magnetic and non-magnetic materials: To ensure precision and accuracy, the Destacker System is equipped with double sheet control on each unit.

This feature effectively detects and prevents double sheet feeding for both magnetic and non-magnetic materials, maintaining consistent quality throughout the production process.

Main Parts of Destacker

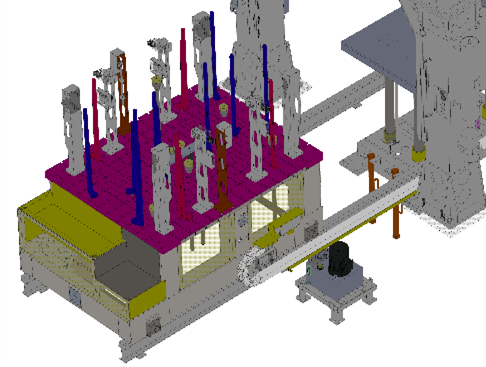

Destacker Loading Station

The destacker loading station is a component of a material handling system that is used to unload or load materials from or onto a destacker machine.

A destacker machine is typically used in industries such as manufacturing, packaging, and logistics to automatically separate and feed individual items or components from a stack or pallet. The destacker loading station is the area where the materials are placed or removed from the destacker machine.

In the case of unloading, the destacker loading station allows for the efficient removal of materials from a stack or pallet. The destacker machine will typically use mechanical or vacuum systems to lift or separate individual items from the stack, and these items are then transported and positioned for further processing or packaging.

In the case of loading, the destacker loading station provides a location for materials to be placed onto the destacker machine. This can involve placing stacks or pallets of materials onto a conveyor system or other feeding mechanism that will transport the materials into the destacker machine for separation and processing.

The destacker loading station is designed to facilitate the smooth and efficient flow of materials into or out of the destacker machine, ensuring proper handling and minimizing downtime. It may also include safety features such as guards or sensors to prevent accidents or damage during the loading or unloading process.

Overall, the destacker loading station is a critical component of a material handling system that enables the effective operation of a destacker machine, streamlining the handling and processing of materials in various industries.

Truss destacker and reclaimer

The Truss destacker and reclaimer is a machine used in the construction industry to handle and sort truss components. It is typically used in the manufacturing or assembly of roof trusses or floor trusses.

The destacker function of the machine involves unloading truss components from a stack or pallet and arranging them in a specific order for assembly. This process helps to ensure efficient and organized truss production.

The reclaimer function of the machine involves collecting and sorting truss components that have been disassembled or are no longer needed. This allows for the reuse or recycling of these components, reducing waste and optimizing material usage.

Overall, the Truss destacker and reclaimer is a valuable tool in truss manufacturing and assembly, improving productivity, efficiency, and material management in the construction industry.

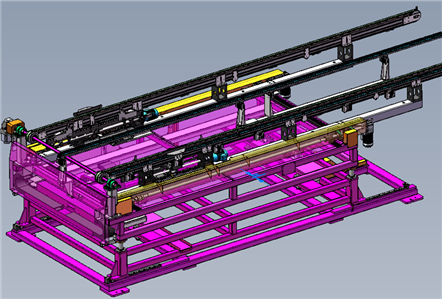

Magnetic belt conveyor

A magnetic belt conveyor is a type of conveyor system that uses magnets to move and transport objects along a conveyor belt. It is commonly used in industries such as mining, recycling, and material handling.

The magnetic belt conveyor operates by using a magnetic field to attract and hold ferrous materials on the conveyor belt. This magnetic attraction allows for the transportation of items that would otherwise be difficult or impossible to move using traditional conveyor systems.

The conveyor belt itself is typically made of a durable material such as rubber or fabric, and it is equipped with magnets or magnetic plates. These magnets generate a magnetic field that attracts and holds ferrous materials as they move along the conveyor.

Magnetic belt conveyors are often used for the separation and sorting of ferrous materials from non-ferrous materials. They can also be used to transport objects in a controlled manner, as the magnetic force holds the items in place and prevents them from sliding or falling off the conveyor belt.

Overall, magnetic belt conveyors offer an efficient and reliable solution for the transportation and separation of ferrous materials in various industries. They provide a safe and effective way to move objects along a conveyor belt while utilizing the power of magnets.

Video of Destacker