Straightener Machine HS-B (1.0-6.0mm)

Applicable Material

Suitable for vary kind of coil material, such as Galvanized steel, Stainless steel, CR Steel, HR Steel, Galvanized steel, Stainless steel, Aluminum, Cooper etc.

Applicable Coil Width: 1600mm

Applicable Coil Thickness: 1.0-6.0mm

Speed: 15m/min

Applications: Pressing Line/Metal Stamping Line

Brief Profile of Metal Straightener Machine

Straightener machine usually consists of 7 pieces of roller, up three and down four rollers, including transfer rollers before and after the leveling rollers. The machine also typically has a handle for fine adjustment of the leveling thickness accuracy.

SUNRUI straightening machines have worm gears and worm screw adjustment systems, which provide a higher level of precision by allowing for more accurate adjustments to be made to the leveling process. These machines are typically more expensive than standard straightening machines but offer excellent accuracy and precision.

The straightening machine is used in various industries, including automotive, aerospace, construction, and manufacturing, to straighten and smooth out metal sheets or strips that have become bent or distorted. By using a straightener machine, manufacturers can improve the quality of their products and increase productivity by reducing the need for post-processing to fix defects caused by bent or warped metals.

In summary, a straightener machine is an industrial machine used for straightening metal sheets or strips that have become bent or warped during handling or processing. It typically consists of three or four rollers and can include a handle for fine adjustment of leveling thickness accuracy.

Application of Metal Straightener Machine

Metal sheet straightener machine is suitable for all kinds of metal sheet stamping, such as the hardware parts, home appliances, furniture hardware, motorcycle accessories, mobile phone accessories, computer accessories and so on.

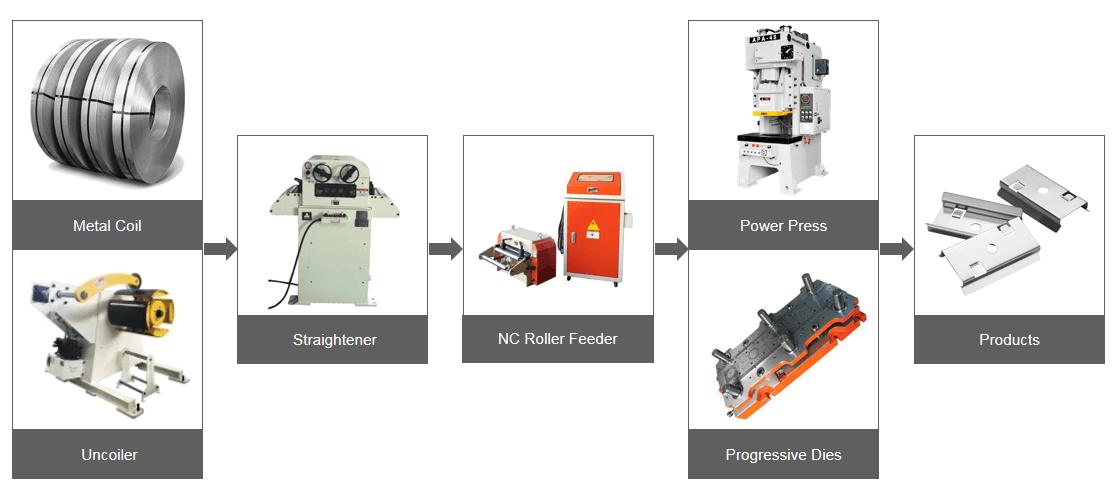

The configuration of metal sheet stamping line.

Step-1: Uncoiler machine, Loading coil and uncoilling coils

Step-2: Metal straightener machine, leveling the strips and lead it to feeder machine.

Step-3: Nc Servo Feeder machine, Feed coil to press machine.

Step-4: Power press machine with the moulds,pressing to the end product.

Feature of Metal Straightener Machine

● This type is suitable for sheet metal coil in thickness from 1.0mm to 6.0mm.

● Used in metal stamping line compacted automatic coil feeder and press machine.

● Worm and gear adjustment of straightener roller, it can guarantee a high precision straightening value adjustment.

● Straightener rollers are electroplated with chrome and has HRC+/-60 hardness.

● Transmission with wheel gear to drive bottom straightener rollers.

● Fast speed: 0-16m/min.

● The rectifying roller is made of solid bearing steel, which is grinded and plated with hard chromium after high frequency heat treatment.

● The machine can be used independently, and it can be used together with MT and DBMT automatic feeder, with better effect.

● The machine adopts large cylinder pressure material, and adopts synchronous worm wheel and worm for correction and adjustment. The handle is rotated once, and the upper wheel can be adjusted with only a drop of 1mm.

● High rigidity mechanical structure, high horsepower output. High speed and stable feeding can be made to improve the production efficiency and prolong the service life of the equipment.

Specification of Metal Straightener Machine

| Model | HS-300B | HS-400B | HS-500B | HS-600B |

| Coil Width | 300mm | 400mm | 500mm | 600mm |

| Thickness | 1.0-6.0mm | |||

| Straightener Roll | Ø90mm * 9pcs | |||

| Pinch Roll | Ø120mm * 2pcs | |||

| Pressure | Cylinder Roller Pressing Way | |||

| Adjustment | Eccentric turbine worm roller adjusting | |||

| Power | 5 HP | 7.5 HP | ||

| Speed | ||||