Straightener Machine TL (0.4-2.2mm)

Applicable Material

Suitable for vary kind of coil material, such as Galvanized steel, Stainless steel, CR Steel, HR Steel, Galvanized steel, Stainless steel, Aluminum, Cooper etc.

Applicable Coil Width: 20mm-1300mm

Applicable Coil Thickness: 0.4-2.2mm

Speed: 15m/min

Applications: Pressing Line/Metal Stamping Line

Brief Profile

Metal sheet straightener machine offers a rough and precision straightener that can process material width up to 1300mm, and can adjusted to handle stock thickness between 0.4-2.2mm, this is the optimum model for processing all kinds of precision components which require outstanding straightening performance.

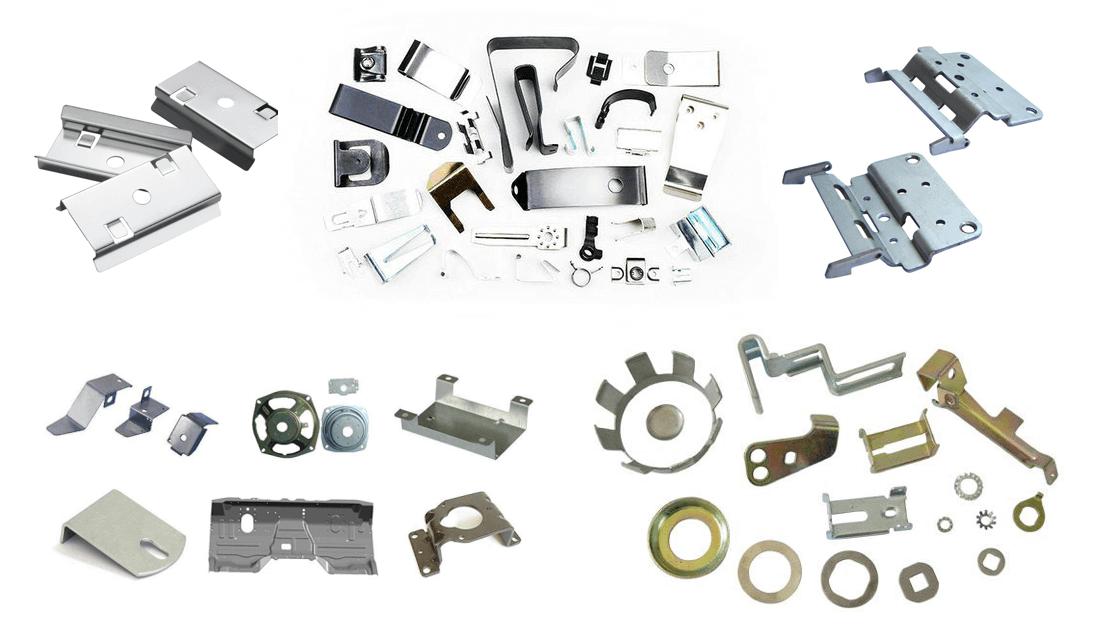

Application

Metal sheet straightener machine is suitable for all kinds of metal sheet stamping, such as the hardware parts, home appliances, furniture hardware, motorcycle accessories, mobile phone accessories, computer accessories and so on.

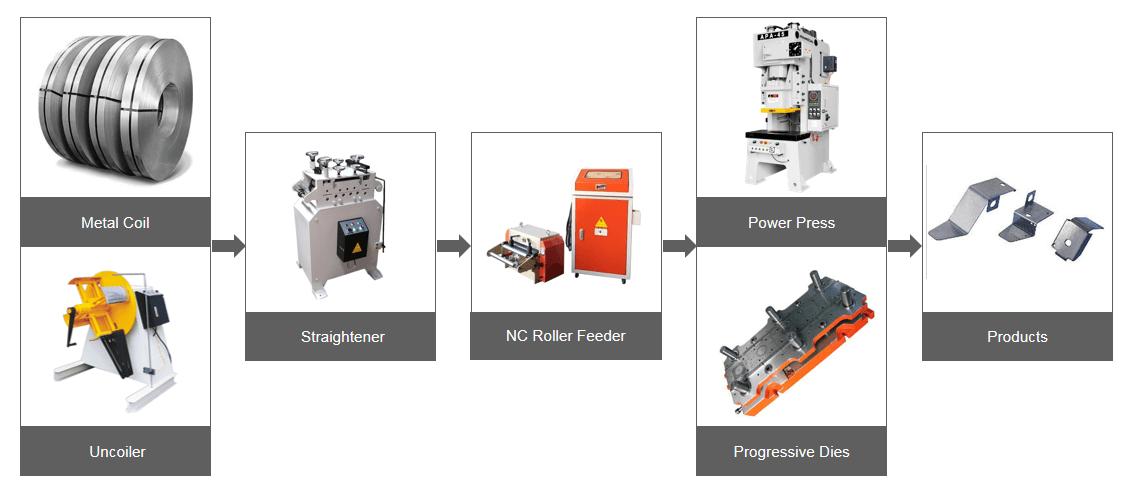

The configuration of metal sheet stamping line.

Step-1: Uncoiler machine, Loading coil and uncoilling coils

Step-2: Metal straightener machine, leveling the strips and lead it to feeder machine.

Step-3: Nc Servo Feeder machine, Feed coil to press machine.

Step-4: Power press machine with the moulds, pressing to the end product.

Feature

● This type is suitable for material thickness: 0.4-2.2mm.

● Suitable for all kinds of metal coil automatic straightening, easy to operate.

● Suitable for metal parts, electron, electrical appliance, toy and auto parts continuous pressing production, straightening.

● The cheapest price machine, High quality, lowest maintenance.

● The rectifying roller is made of solid bearing steel, which is grinding and plated with hard chromium after high frequency heat treatment.

● The machine can be used independently, and it can be used together with MT and DBMT automatic feeder, with better effect.

● The machine adopts large cylinder pressure material, and adopts synchronous worm wheel and worm for correction and adjustment. The handle is rotated once, and the upper wheel can be adjusted with only a drop of 1mm.

● High rigidity mechanical structure, high horsepower output. High speed and stable feeding can be made to improve the production efficiency and prolong the service life of the equipment.

Specification

| Model | TL-200 | TL-300 | TL-400 | TL-500 | TL-600 | TL-700 | TL-800 |

| Coil Width | 200mm | 300mm | 400mm | 500mm | 600mm | 700mm | 800mm |

| Coil Thickness | 0.4-2.2mm | ||||||

| Straightening Rolls | Ø50mm * 7pcs | Ø60mm * 7pcs | |||||

| Pinch & Feed Rolls | Ø60mm * 2pcs/Ø80mm * 2pcs | Ø70mm * 2pcs/Ø98mm * 2pcs | |||||

| Power | 1 HP | 2 HP | 3 HP | 5 HP | |||

| Speed | 16m/min | ||||||

| Model | HS-300A | HS-400A | HS-500A | HS-600A | HS-300B | HS-400B | HS-500B | HS-600B |

| Coil Width | 300mm | 400mm | 500mm | 600mm | 300mm | 400mm | 500mm | 600mm |

| Thickness | 0.5-4.5mm | 1.0-6.0mm | ||||||

| Straightener Roll | Ø70mm * 9pcs | Ø90mm * 9pcs | ||||||

| Pinch Roll | Ø95mm * 2pcs | Ø120mm * 2pcs | ||||||

| Pressure | Cylinder Roller Pressing Way | |||||||

| Adjustment | Eccentric turbine worm roller adjusting | |||||||

| Power | 5 HP | 7.5 HP | 5 HP | 7.5 HP | ||||

| Speed | 15m/min | |||||||