S-Loop Precision Straightener JMS (0.3-1.2mm)

Applicable Material

Suitable for silicon steel sheet, stainless steel sheet, carbon steel, etc.

Applicable Coil Width: 20mm-300mm

Applicable Coil Thickness: 0.3-1.2mm

Speed: 60m/min

Applications: Pressing Line/Metal Stamping Line

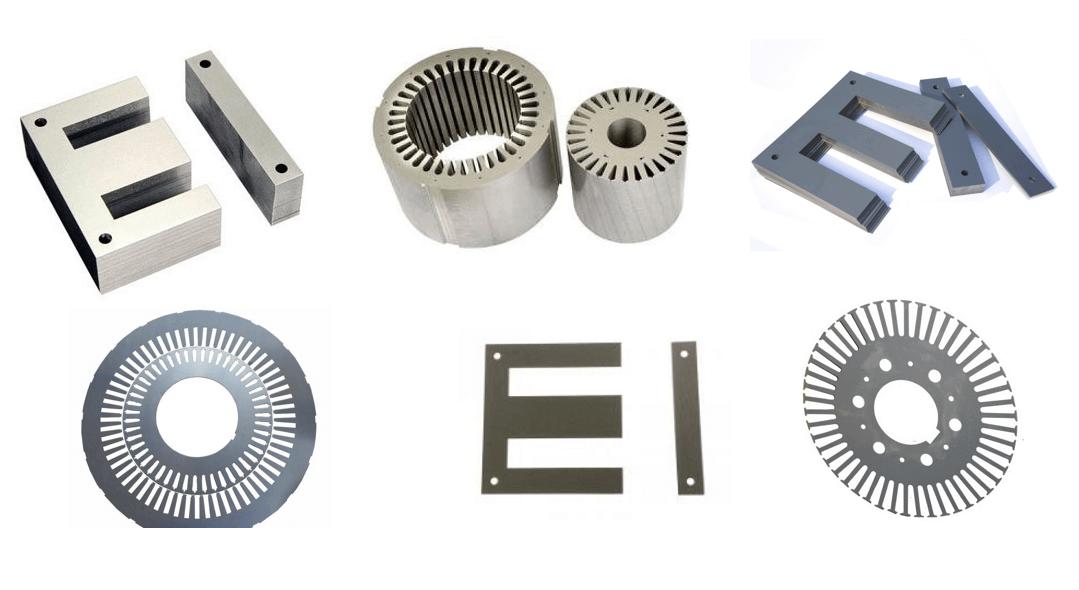

JMS is ideal for high speed Stator & rotor and EI lamination stamping line

Brief Profile of S-Loop Precision Straightener

The speed of the S loop high-speed straightener can reach 60m/min, making it a fast and efficient machine for high-speed stamping operations. It is typically used in conjunction with a double head decoiler machine, high-speed gear machine, and H-frame high-speed press machine, making it suitable for motor rotor and stator lamination stamping.

The S loop high-speed straightener offers several advantages over conventional straightening machines, including:

1. High speed: The machine can operate at high speeds, improving productivity and output.

2. Accurate straightening: The machine can accurately level the coil material, resulting in consistent and uniform parts.

3. Eliminates stress: The machine helps to eliminate stress in the metal coil material, resulting in better quality parts.

4. Adaptable to different materials: The machine can handle a variety of different metal coil materials, making it versatile for use in different stamping applications.

In summary, the S loop high-speed straightener machine is a powerful industrial machine used for straightening metal coil materials before they are fed into a stamping machine. It improves the quality and quantity of punched products, and can operate at high speeds, making it a valuable machine for high-speed stamping operations.

Application of S-Loop Precision Straightener

JMS S-loop straightener is used in stator and rotor lamination stamping and EI lamination stamping line.

The configuration of metal sheet stamping line.

Step-1: Double Head Decoiler machine, Loading coil and uncoilling coil.

Step-2: High speed S Loop Straightener machine, leveling the strips.

Step-3: High speed Cam Feeder machine, Feed coil to press machine.

Step-4: High speed press machine with the moulds, pressing to the end product

Feature of S-Loop Precision Straightener

● This type is suitable for material thickness: 0.3-1.2mm.

● Suitable for all kinds of metal coil automatic straightening, easy to operate.

● Suitable for metal parts, electron, electrical appliance, toy and auto parts continuous pressing production, straightening .

● The rectifying roller is made of solid bearing steel, which is grinding and plated with hard chromium after high frequency heat treatment.

● It has a S shape loop to store the metal sheet, besides with some infrared sensors, so can work with high speed feeder synchronously.

● The machine can be used independently, and it can be used together with MT and DBMT automatic feeder, with better effect;

● High rigidity mechanical structure, high horsepower output.High speed and stable feeding can be made to improve the production efficiency and prolong the service life of the equipment.

Specification of S-Loop Precision Straightener

| Model | JMS-200 | JMS-300 |

| Coil Width (mm) | ~200 | ~300 |

| Coil Thickness (mm) | 0.1 - 1.2 | |

| Feeding Speed | 0 - 60 m/min | |

| Motor | 2HP | |

| Inverter | Delta, Taiwan | |

| Straightener Roller | 5pcs on top + 6pcs on bottom | |

| Pinch Roller | 2pcs | |

| Roller Adjustment | 4 points fine micro adjustment | |

| Loop Control | Photo-electric Sensing Device | |