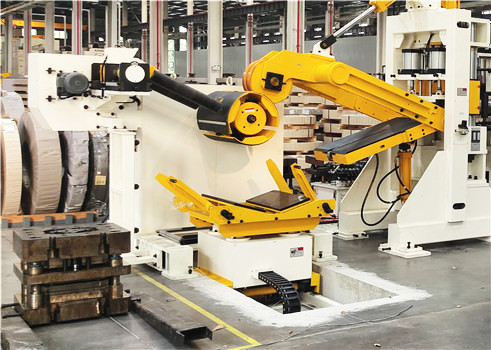

Fine Coil Blanking Line with Double-stage Straightener machine for brake pads

The whole coil blanking line includes the below parts:

Decoiler Machine with coil car

Coil threading device

Hydraulic shearing machine for head and tails cutting

Double-stage Straightener machine

The loop bridge device

NC Servo Feeder Machine

Press machine/ Hydraulic press machine with molds

Conveyor belt

Why Recomment Fine Coil Blanking Line with Double-stage Straightener machine?

This Fine coil blanking Line with Double-stage Straightener machine is a new automatic production line specially developed for blanking production of medium and thin metal sheet plates with higher yield strength.

The straightener part of the coil blanking line adopts the structure of double stages straightener machine and universal joint full shaft transmission, which better ensures the straightener accuracy. The surface of the clamping roller is treated with electroplated hard chrome, which increases the friction between the roller and the coil strips, so as to ensure that the feeding process will not slip during the feeding process .

The innovative mechanical structure minimizes the working space required by the whole machine, with the high-definition operation screen and the operation safety protection system, even first-time users can operate with peace of mind.

The sound humanized design of the operating system shortens the preparation work. Advanced automatic diagnosis system to assist the operator to quickly control the superior performance of the machine. The design concept of enhancing the safety factor makes the equipment safe and has a longer service life; and the control system has the memory function with a large capacity of product parameter information library, and complete machine fault warning system.

The configuration of Fine Coil Blanking Line with Double-stage Straightener machine

Decoiler Machine with coil car

The decoiler machine of this coil blanking line can loading at least 8000kgs coils.

The Spindle of decoiler machine is driven by frequency conversion deceleration motor double-row large-pitch chain. Apply a reverse pull to the leveler, and establish a constant back tension between the two to ensure that the sheet between the uncoiler and the leveler is always in a tensioned state. Use the sensor to detect the change of the outer diameter of the material to adjust the tension of the inner and outer diameters.

The pressure arm is driven by hydraulic which can prevent the coil strips from loosening after the belt is removed. During the automatic operation, the pressure arm will rotate with the diameter of the material roll to prevent the coil strips from unraveling.

The limiting arm arm which is Located on the upper right of the decoiler, the limiting arm can rotate with any external force without power. It is used to prevent the coil strips from slipping during the feeding process.

Coil threading device

When feeding the coil strips, the pulling upper roller can be manually opened and closed, and with the coil threading device, it can smoothly, easily and safely clamp the coil strip heard and lead the coil strip head from the uncoiler to the leveler.

The coil threading device includes machine frame, sheet traction platform, pulling roller (pulling wheel), straightening wheel.

The sheet traction platform ensures that the coil strip head enters the feeding roller smoothly. Then the sheet traction platform swings to the low position to lead the strip enter to the follow-up equipment through the input roller. In the automatic state, the rollers run synchronously with other machine.

Hydraulic shearing machine for head and tails cutting

It’s used to cut the coil heads and tails

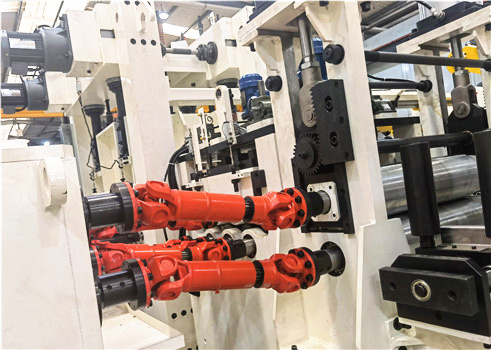

Double-stage Straightener machine

Hydraulic shearing machine for head and tails cutting The double-stage precision leveling structure is adopted which includes 2 straightener sections, the large-rolling leveling rollers in the front section are rough, and the rear section adopts a six-fold leveling structure for precision leveling.

Precision leveling is a metal plate with a large number of staggered leveling rollers to achieve multiple levels. The amount of bending can be adjusted electrically. After repeated bending of the metal sheet, the metal fibers tend to be consistent, and the internal stress of the material is eliminated at the same time. The straightened coil strips will be feeding into the press machine according to the set feeding length and speed.

The main purpose of this mechanism is to correct material curling (length L direction) to make the surface smooth, and it may not be completely corrected when there is local stretching on the material surface. In addition, the width direction (C direction) of the coil cannot be corrected.

Front section roughing roller combined 5 pieces leveling rollers which are arranged as 3 up and 2 down,making the coil strip more accurate and safe. On the leveling rollers, a set of auxiliary rolls with one heavy type is arranged on the upper and lower sides respectively. Prevent the deformation of the leveling roller and maintain the concentricity of the leveling roller. The leveling roller is made of bearing steel, which has been quenched and tempered, lathe processed, intermediate frequency quenched, ground, hard chrome plated, and ground again.

Rear stage correction roller combined 15 pieces leveling rollers which are arranged as 7 upper and 8 lower,making the coil strip more accurate and safe. On the leveling rollers, a set of auxiliary rolls with one heavy type is arranged on the upper and lower sides respectively. Prevent the deformation of the leveling roller and maintain the concentricity of the leveling roller. The leveling roller is made of bearing steel, which has been quenched and tempered, lathe processed, intermediate frequency quenched, ground, hard chrome plated, and ground again.

Each straightening roller is individually driven by a distribution gear via a cardan shaft, and this special design can make high tension and thick plate materials meet more precise leveling requirements and a more stable leveling effect.

The loop bridge device

The loop bridge device which is automatically guides straightened and smooth materials into the feeder is limited to manual operation on the touch screen. Before automatic operation, it must be lowered to the bottom of the pit to meet the safety conditions before operation.

NC Servo Feeder Machine

The NC servo feeder is driven by a vertical servo motor which can be suitable for much wider metal stamping application and servo motor drives the feed roller through a synchronous belt wheel to achieve precise feeding. It uses the release signal provided by the cam of press machine to release the accumulated error through the cylinder.

The NC servo feeder adopts a famous brand touch screen and servo motor and parameters such as feeding length and feeding speed can be set simply and quickly. At the same time, it is equipped with a remote handle, which greatly reduces the debugging time during testing process.

And what's more, the multi-stage feeding can meet the needs of special processing. When it's equipped with multi-engineering progressive dies for stamping production, the feeding length are often not completely consistent, so multi-stage feeding function is required, our NC servo feeder can be equipped with 99-stage feeding function, which can fully meet the needs of customers for multi-station molds.

Video of Fine Coil Blanking Line with Double-stage Straightener machine