How a Turnkey Stamping Line Makes Perfect Discs: A Look at Decoiler, Straightener, Servo Feeder & Press

In modern manufacturing, efficiency and precision are non-negotiable. For high-volume production of simple yet critical components like metal discs—also known as blanks—a well-integrated turnkey stamping line is the solution of choice. Unlike assembling individual machines, a turnkey line is a pre-engineered system where all components are designed to work in perfect harmony from the start.

The Seamless Workflow: From Coil to Finished Disc

This article breaks down the seamless journey of a steel coil into a finished disc, focusing on the six core components that make it possible: the Decoiler, Straightener, Servo Feeder, Stamping Press, Precision Die, and Conveyor System.

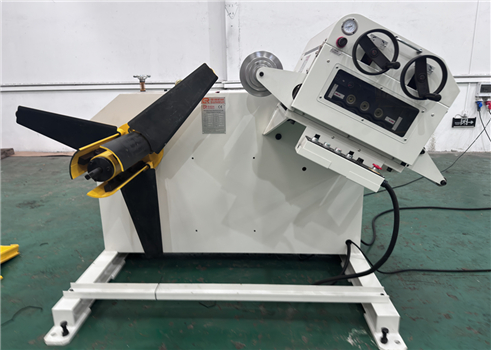

1. The Decoiler: Feeding the Raw Material

The process begins at the decoiler. This machine holds the large, heavy master coil of steel (or other metal) and acts as the line's reservoir. Its primary function is to pay out the material smoothly and consistently into the next stage. Modern decoilers often include tension control or loop systems to ensure the coil unwinds without stretching or damaging the material, providing a steady supply to the line.

2. The Straightener: Ensuring Perfect Flatness

As the metal strip leaves the decoiler, it retains natural curves and internal stresses from being coiled. This is where the straightener becomes critical. It consists of a series of rolls that bend the material back and forth in opposite directions, effectively "ironing out" any coils, twists, or minor imperfections. Delivering perfectly flat material to the press is essential. Any curvature or residual stress would lead to misalignment in the die, causing poor-quality stamps, jams, or even tooling damage.

3. The Servo Feeder: The Brain of Precision

The flattened strip then enters the servo feeder, arguably the most technologically advanced component in the feeding process. This device is responsible for advancing the material a precise distance—the exact feed length—into the press with each cycle. Unlike mechanical feeders, a servo feeder uses a programmed servo motor for movement. This allows for:

Micron-Level Accuracy: Essential for maintaining perfect registration in the die.

Flexible Feed Lengths: Easy adjustment via the control panel for different part sizes.

Perfect Synchronization: Its motion profile is electronically synced with the press cycle, ensuring smooth acceleration and deceleration, which reduces material stress and wear.

The servo feeder is what transforms a simple material feed into a precise, programmable step, guaranteeing that each disc is punched in the correct location every single time.

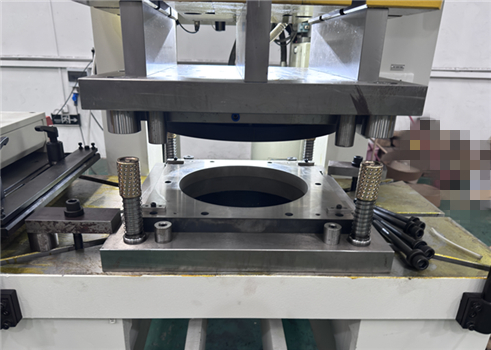

4. The Stamping Press & Precision Die: The Heart and Soul of Production

The material now reaches the stamping press—the powerhouse of the line. Here, the precision die performs the critical transformation. While the press provides the necessary tonnage and motion, the die is the custom-engineered tool that defines the final product. For disc production, the die features hardened steel punches and dies that cleanly shear the metal on each press stroke.

The precision die is designed for longevity and accuracy, often incorporating:

Guided Pilots: To ensure the strip is perfectly positioned before cutting.

Specialized Coatings: To reduce friction and wear.

Optimized Clearance: Between punch and die for clean cuts and minimal burrs.

The synchronized action of the servo feeder and press ensures the material is perfectly positioned in the die cavity for each stroke, producing consistent discs with exact tolerances.

5. The Conveyor System: Automated Material Handling

Once the disc is stamped, two paths are managed automatically:

Finished Parts Conveyor: This belt or chute system gently collects the stamped discs and transports them to a collection bin, stacking station, or the next processing stage (like deburring or coating). This automation prevents part damage and eliminates manual handling.

Scrap Conveyor: Simultaneously, the skeleton scrap (the remaining web of metal with holes) is cut and routed away by a dedicated scrap conveyor. This keeps the work area clean, prevents scrap from interfering with the press or finished parts, and efficiently channels waste material for recycling.

Why a Turnkey System is Superior for Disc Production

Integrating these six components into a single turnkey system offers decisive advantages over a piecemeal approach:

Optimized Performance: All machines are matched for speed, capacity, and control compatibility from the design phase.

Reduced Complexity: A single-source supplier means coordinated installation, one set of manuals, and unified technical support.

Faster ROI: The line is designed for maximum uptime, quick setup changes, and consistent quality from day one, accelerating production ramp-up.

Complete Automation: From feeding to part collection and scrap removal, the entire process is hands-off, boosting safety and efficiency.

Space & Workflow Efficiency: The layout is pre-planned for a logical, compact material flow, saving floor space and minimizing bottlenecks.

Conclusion

Producing a simple metal disc is a deceptively complex task that demands consistency, speed, and absolute precision. A turnkey stamping line that integrates a decoiler, straightener, servo feeder, stamping press, precision die, and conveyor system transforms this task into a flawless, automated routine. By ensuring each component is perfectly synchronized with the next—from feeding the coil to collecting the finished part and managing scrap—this approach represents the pinnacle of efficient, reliable, and high-quality metal blank manufacturing. For any operation looking to produce discs or similar blanks at scale, investing in a turnkey solution is not just a purchase—it's a strategic decision for long-term productivity and competitiveness.

How a Turnkey Stamping Line Makes Perfect Discs Video