How SUNRUI's Coil Feed Line Revolutionized Production for an Automotive Stamping Manufacturer

Automotive stamped parts are essential components in the manufacturing of vehicles, playing a vital role in their structure and functionality. From brackets to end caps and dust covers to spring seats, these metal stamped parts are integral to vehicle assembly. In this article, we will explore the characteristics of automotive stamped parts, the production processes involved, and key design considerations, along with the benefits of advanced technologies like the SUNRUI COIL FEED LINE.

What's the Coil Feed Line? The Foundational System for Modern Stamping

A Coil Feed Line is a fully integrated, automated material handling system that serves as the critical first stage in metal stamping production. Its core function is to efficiently and precisely process raw metal coils—the primary material form for high-volume manufacturing—into a continuous, flawlessly flat strip ready for the stamping press.

Think of it as the "heart and circulatory system" of the press shop: it reliably feeds the lifeblood (material) to the "muscle" (the stamping press) with exact precision. For automotive manufacturers, where part consistency, material yield, and production uptime are paramount, a high-performance coil feed line is not optional; it's a strategic necessity for achieving quality, competitiveness, and profitability.

Core Components & Function:

Decoiler / Uncoiler: The starting point. It securely holds the heavy metal coil (weighing several tons) and controls its unwinding, providing consistent tension.

Straightener / Leveler: The quality gate. This unit, through a series of precision rollers, systematically removes the inherent curvature (coil set) and any crossbow or edge wave from the material. It ensures the metal is perfectly flat before entering the press, which is crucial for forming accurate parts.

Servo Feeder: The brain and precision actuator. This computer-controlled device grips the material and advances it into the press die with exact, repeatable length (±0.01mm-level accuracy). This step is critical for the dimensional integrity of every stamped part.

Advanced systems, like the SUNRUI MFL4-1300GF, integrate these modules with Programmable Logic Controller (PLC) automation, adding features like automatic threading, loop control for constant material flow, and quick-change tooling, transforming them from basic feeders into intelligent production enablers.

What're Automotive Stamped Parts?

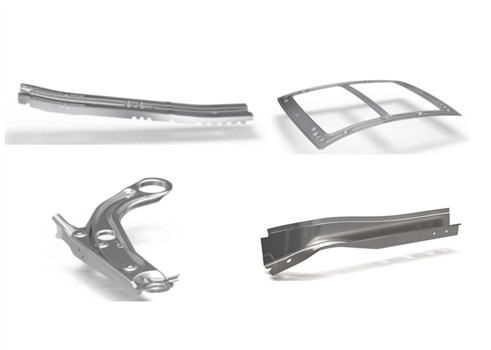

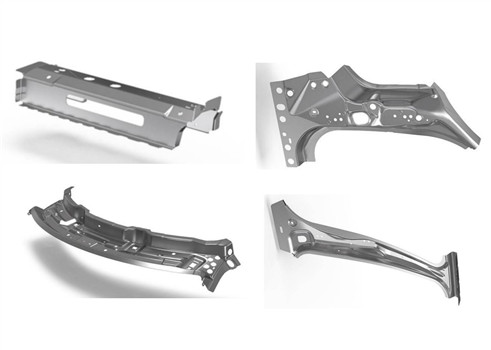

Automotive stamped parts are metal components produced through a stamping process, which involves shaping and cutting material, typically sheet metal, using specialized dies. These parts are characterized by their lightweight nature, excellent rigidity, and high strength, making them ideal for automotive applications. Common examples include:

Brackets: Used for structural support.

Spring Seats: Essential for holding springs in place.

End Caps: Often used to close off components.

Covers: Protect internal parts from dust and debris.

Compression Valve Covers: Integral to engine assembly.

The Client's Challenge: Scaling Up with Precision

The client, a Tier 2 supplier specializing in chassis components and body reinforcements for trucks and SUVs, needed to upgrade their production capability. Their existing system could not handle the material specifications for new, larger part designs, creating a critical barrier to growth. Specific challenges included:

Material Limitation: Existing equipment maxed out at 1000mm coil width and 3.0mm thickness, preventing bids on contracts requiring heavier-gauge, wider parts.

Production Inefficiency: Manual intervention for coil changes and threading resulted in an average of 45 minutes of press downtime per coil changeover.

Feed Inconsistency: For their existing high-strength steel parts, minor feed length variations (±0.3mm) caused issues in multi-stage progressive dies, leading to a 3.2% rejection rate.

Demanding Schedule: Needed a robust solution that could integrate quickly with their 800-ton stamping press and withstand 24/5 production cycles.

The Precision Solution: SUNRUI MFL4-1300GF Coil Feed Line

SUNRUI engineers recommended the MFL4-1300GF, a heavy-duty, servo-driven feed line designed for demanding automotive applications. Its key features directly targeted the client's pain points:

High-Capacity Processing: Engineered to handle coils up to 1300mm in width and 6.0mm in thickness, immediately opening new market opportunities.

NC Servo Feed with Loop Control: A closed-loop servo system guaranteed exceptional feed accuracy of ±0.01mm, essential for complex progressive stamping of safety-critical components.

Rapid, Automated Changeover: The line featured a motorized decoiler with integrated peel-off and threading aids, slashing coil changeover time by over 70%.

Heavy-Duty 9-Roller Straightener: Equipped with anti-deflection rollers to ensure perfect flatness across the full 1300mm width, critical for part consistency.

Ruggedized Construction: Built with reinforced frames and high-wear components to ensure longevity and minimal maintenance under continuous high-tonnage production.

Implementation & Quantifiable ROI

The Coil feed line was installed during a scheduled shutdown. Within one week, it was fully integrated and operational.

Measurable Outcomes (After 8 Months):

| Key Performance Indicator | Before Installation | After Installation | Improvement |

|---|---|---|---|

| Maximum Processable Material | 1000mm (W) x 3.0mm (T) | 1300mm (W) x 6.0mm (T) | New Product Capability |

| Feed Length Accuracy | ±0.3mm | ±0.01mm | Rejection Rate ↓ 78% |

| Average Coil Changeover Time | 45minutes | 12 minutes | 73% Faster |

| Overall Equipment Effectiveness (OEE) | 67% | 89% | +22 Points (32% Rel. Increase) |

| Business Outcome | Limited to small/medium parts | Awarded contracts for 2 new large structural parts | Direct Revenue Growth |

Client Verification: A Strategic Enabler

“The MFL4-1300GF wasn’t just a replacement; it was a strategic upgrade that removed our biggest constraint,” confirmed the client’s Operations Director. “We’re now competing for and winning projects we previously couldn't touch. The precision and reliability are foundational to our quality goals.”

The investment paid for itself in under 15 months through a combination of efficiency savings, scrap reduction, and new revenue directly attributable to the expanded capability.

Conclusion: Building Automotive Manufacturing Futures

This case demonstrates that in the competitive automotive supply chain, production equipment must be a strategic asset for growth. The SUNRUI MFL4-1300GF Coil Feed Line provided more than improved performance; it delivered new manufacturing capabilities, superior precision for quality-critical parts, and the robustness for continuous high-volume output, positioning the client for future growth in the evolving automotive market.