Customized Coil Feeding Line For Producing Steel Spacers In Building

Recently, one of our customer is looking for a coil Feeding Line for producing steel spacers in building.

The Coil Feed Line for producing steel spacers in building is a specialized production system that is used for the mass production of steel spacers.

These spacers are widely used in various construction applications and are typically produced from steel coil material.

What's The Steel Spacer?

Spacers are essential components used in building construction to provide even spaces between structural elements, such as reinforcement bars (rebars) in concrete. They act as a support for these elements to maintain a specific distance between them and provide structural strength and stability.

Steel spacers, made from high-strength steel, are commonly used in the construction of high-rise buildings, bridges, and other large structures where high strength and durability are required. They come in various sizes, shapes, and configurations depending upon the project requirements.

A typical Coil Feed Line For Producing Steel Spacers In Building

A typical Coil Feed Line for producing steel spacers in building consists of the following main components:

The unwind straightener is used to uncoil the raw material and remove any curvature or bend. The straightened material is then fed through the servo feeder, which controls the feeding rate and the length of material to be fed into the press for stamping operations.

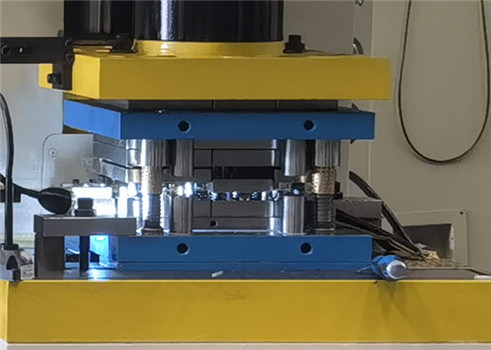

The Stamping press is the core component of the line, and it is used to stamp the metal components from the fed material. The press is typically equipped with a die set customized for the specific component being produced, and it applies a high amount of force to the material to cut or form it into the desired shape.

Stamping dies are specialized tools used to cut or form metal sheets and other materials into the desired shape or size. And stamping dies in manufacturing is critical to maximizing production uptime and minimizing downtime.

After the metal component is stamped, an automated parts conveyor removes it from the press and moves it further down the production line for additional processing, such as heat treatment, or as a finished product.

The Coil Feeding Line is a complete metal stamping system that can be configured in various ways to suit different production requirements. It can be equipped with additional components that improve the performance and safety of the production process, such as die lubrication systems, safety curtains, and automatic die changing systems. These features increase the efficiency and output of the production line while maintaining a high level of quality and precision.

The Coil Feed Line for producing steel spacers in building is designed for high-speed, high-volume production of steel spacers with precise dimensions and consistency. It is capable of achieving significant throughput rates and reducing material waste, making it highly efficient. The system is widely used in various construction projects that require high-quality steel spacers at competitive prices.

In summary, the Coil Feed Line for producing steel spacers in building is a specialized production system that enables manufacturers to mass-produce high-quality steel spacers quickly and efficiently. It is a valuable solution that is widely used across various construction projects that require stamped steel spacers, including high-rise buildings, bridges, and other infrastructure projects.