How to Manufacture License Plates Efficiently? The Ultimate Guide to Automated Stamping Lines

Are you struggling with slow, inconsistent, or labor-intensive license plate production? In an industry where efficiency, durability, and strict regulatory compliance are non-negotiable, a piecemeal equipment approach can cripple your output and profitability.

This guide cuts through the noise. We’ll move beyond basic theory to provide a complete technical blueprint for a modern, automated license plate stamping line. You will learn the critical engineering considerations, from material handling to final embossing, that separate a high-performance production system from an unreliable one. For manufacturers aiming to scale operations, reduce waste, and guarantee every plate meets exacting standards, this is your essential resource.

Core Challenges in Modern License Plate Manufacturing

Before designing a solution, we must understand the precise demands of the product itself. A license plate is a deceptively simple component with rigorous requirements:

Material Precision: Predominantly 0.9-1.2mm thick aluminum alloy (e.g., 5052 or 6061), chosen for its optimal balance of lightweight durability, corrosion resistance, and malleability for embossing.

Dimensional Integrity: Global standards vary (e.g., 305x152mm for North America, 520x110mm for EU), requiring equipment capable of quick, accurate changeovers for different markets.

Process Criticality: The sequence—blanking, cleaning, embossing, coating—demands perfect synchronization. Any inconsistency in flatness, feed length, or stamping pressure results in scrap, rework, and failed quality audits.

The bottleneck for most manufacturers isn't a single machine, but the lack of integration between stages. Manual coil loading, inconsistent feeding, and standalone presses create a cascade of inefficiencies.

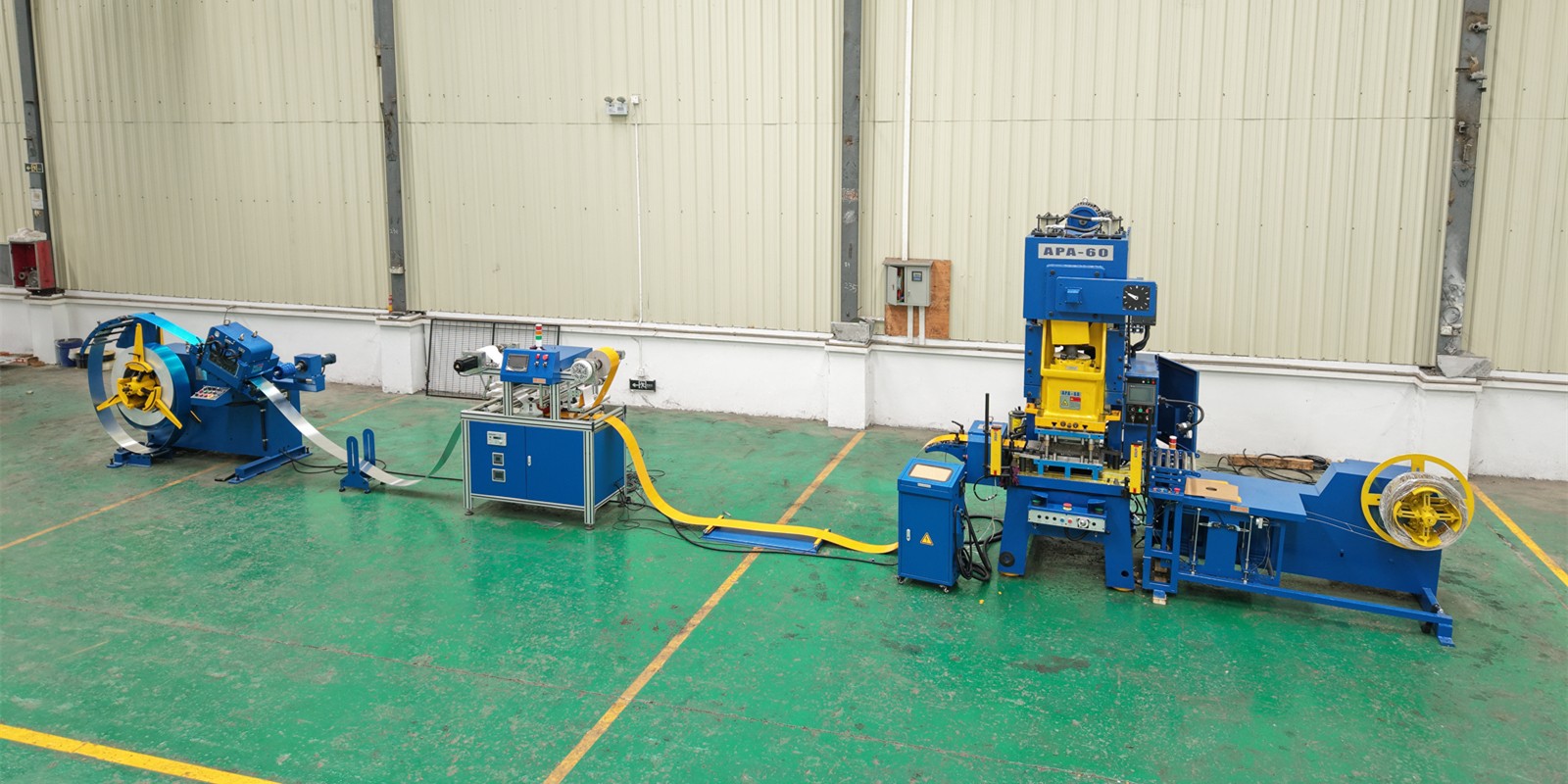

The Integrated, Turnkey Stamping Line Solution

A high-output license plate factory doesn't use isolated machines; it operates a synchronized production system. Here is the anatomy of a true turnkey line, where each component is engineered to work in unison with the next.

Stage 1: Precision Material Preparation & Feeding

This foundation stage determines the flatness and consistency of every subsequent operation.

High-Precision Decoiler & Straightener: A robust, combined unit that unwinds the master coil and actively removes coil memory and internal stresses. Key features include:

Multi-Roller Straightening: A configuration of 7-15 hardened (HRC 58+) rollers that progressively eliminate crossbow and camber.

Closed-Loop Tension Control: Maintains constant material tension from decoiling through to feeding, preventing slippage or stretching.

Result: Outputs perfectly flat, stress-free aluminum strip with flatness held within 0.5mm/m, which is critical for clean blanking and uniform embossing.

NC Servo Feeder: The "brain" of the feeding process. It advances the material with absolute precision for each blanking or embossing stroke.

Micron-Level Accuracy: Utilizing high-torque servo motors, it achieves feed length repeatability within ±0.02mm.

Programmable Flexibility: Feed length and speed are easily adjusted via a touchscreen HMI for different plate sizes and production rhythms.

Perfect Synchronization: Its motion profile is electronically synced with the press cycle, ensuring smooth acceleration/deceleration to minimize material shock.

Stage 2: High-Speed Blanking & Handling

Here, the continuous strip is transformed into individual plate blanks.

High-Speed Blanking Press with Progressive Die: A mechanical or servo press with a custom-designed progressive die performs the critical blanking operation.

Speed & Stability: Capable of operating at 40-80 strokes per minute (SPM), the press must maintain parallelism and rigidity at high speed.

Precision Tooling: The carbide progressive die cleanly shears the aluminum with minimal burr formation. Guided pilots ensure strip positioning is accurate to within ±0.03mm on every stroke.

Automated Scrap Handling: A built-in scrap chopper and conveyor automatically remove and manage the skeleton web, keeping the work area clean and safe.

Stage 3: Automated Cleaning & Surface Prep

Blanks must be perfectly clean for coating adhesion. An automated washing and drying station removes oils, particulates, and oxides, preparing the surface for the reflective film.

Stage 4: Embossing & Final Forming

The core of the line where blanks become identifiable plates.

High-Tonnage Stamping Press (e.g., 60-Ton or 100ton hydraulic press machine Series): This press provides the force necessary for deep-draw embossing of alphanumeric characters.

Precision & Power: A rigid, guided frame ensures the embossing die contacts the plate uniformly, producing crisp, consistent character depth across the entire plate surface.

Programmable Controls: Allows for easy setup and adjustment of stroke length and pressure for different character styles or regional specifications.

Stage 5: Reflective Filming & Curing

The final quality and durability step.

Auto Filming Machine: Applies the pressure-sensitive reflective sheeting with uniform tension and adhesion.

Heated Lamination Rollers: Activate the adhesive and ensure a bubble-free, permanent bond between the film and the embossed aluminum surface.

Precision Registration: Ensures the film is applied squarely and consistently to every plate.

Quantifiable Benefits & ROI of an Integrated Line

Investing in a synchronized system transforms your production economics. Here’s what a turnkey line delivers:

| Performance Metric | Piecemeal Equipment | SUNRUI Turnkey Line | Business Impact |

|---|---|---|---|

| Overall Equipment Effectiveness (OEE) | 50-65% | 85%+ | Maximizes capital utilization, produces more with the same footprint. |

| Production Speed | 15-25 SPM | 40-60 SPM | Output can increase by 60-150%, allowing you to meet larger contracts. |

| Material Yield | 92-95% | 98%+ | Reduces scrap by 3-6%, delivering direct savings on expensive coated aluminum coil. |

| Labor Requirement | 3-4 operators/line | 1-2 operators/line | Cuts direct labor costs by 30-50% and reduces human error. |

| Changeover Time | 45-90 minutes | < 20 minutes | Enables economical small-batch production for custom or regional plates. |

| Quality Consistency | Manual checks, variable | Automated, precision-controlled | Virtually eliminates batch rejections and customer returns. |

Key Takeaway: The return on investment (ROI) for a turnkey line typically comes from multiple, compounding sources: higher throughput, lower scrap, and reduced labor. For a medium-volume producer, this often translates to an ROI period of 3-10 months.

How to Evaluate a Stamping Line Supplier

Choosing the right partner is as critical as the specs. Go beyond the brochure with these steps:

Demand Application-Specific Engineering: A serious supplier will ask detailed questions about your target markets (materials, dimensions, volumes) and propose a tailored line layout, not just a standard catalog.

Request Live or Recorded Run-Offs: Ask to see video of the proposed equipment running actual aluminum coil at the promised speeds. Pay attention to material flow, scrap handling, and control system ease of use.

Verify Control System Integration: Ensure all components (decoiler, feeder, press) are controlled by a unified PLC system with a single HMI. This is the key to seamless operation and easy troubleshooting.

Scrutinize After-Sales Support: What is their mean time to respond (MTTR)? Do they provide comprehensive training, clear manuals, and remote diagnostic support? Global spare parts availability is essential for minimizing downtime.

Your Next Step Toward Automated Production

Transitioning from manual or semi-automated processes to a fully integrated stamping line is the definitive step for any license plate manufacturer aiming for growth and superior quality. It transforms production from a series of potential problems into a predictable, high-output process.

The competitive advantage lies not in any single machine, but in the seamless synergy of the entire system. By focusing on integration, precision, and measurable ROI, you can build a manufacturing operation that is efficient, resilient, and ready to meet future demands.

Ready to engineer your optimized production line? Contact SUNRUI engineering team today for a confidential consultation and a custom line proposal based on your specific output targets and material specifications.

Video of automated license plate stamping line