Driving Efficiency in 2025: The Evolution of Coil Feed Lines and the Rise of SUNRUI MACHINE

In the competitive world of metal stamping and fabrication, the difference between profit and loss often comes down to millimeters and seconds. As we move through 2025, the Coil Feed Line—the backbone of automated stamping—has evolved from a simple material dispenser into a highly intelligent, synchronized system capable of handling the toughest materials on the planet.

What is a Coil Feed Line?

A coil feed line is an automated system designed to take raw sheet metal from a heavy coil and prepare it for a production machine, such as a stamping press. A high-quality line performs three critical tasks in one continuous flow:

Decoiling: Safely unwinding the heavy metal coil.

Straightening: Removing "coil set" (the curvature of the roll) to ensure the material is perfectly flat.

Feeding: Precision-advancing the material into the die at exact intervals and high speeds.

The 2025 Manufacturing Challenge: AHSS

The biggest challenge for manufacturers in 2025 is the widespread use of Advanced High-Strength Steel (AHSS). Industries like automotive are moving toward thinner, stronger steels to reduce vehicle weight without sacrificing safety. These materials possess massive internal tension, making them difficult to flatten and dangerous to handle manually. This challenge has galvanized innovation across the board, with leading brands pushing the boundaries in material science, precision control, and machine durability.

Top Players in the 2025 Market

Several brands have defined the standard for reliability this year. While each brings a distinct focus to solving the AHSS challenge, their collective progress has redefined the capabilities of the entire industry.

ARKU (Germany): The leader in precision leveling technology for heavy plate applications.

SUNRUI MACHINE (China): The 2025 breakout star for High-Performance Value. Sunrui has mastered the balance between heavy-duty engineering and cost-efficiency, becoming the preferred choice for automotive tier-1 suppliers globally.

COE Press Equipment (USA): Known for massive, wide-capacity lines used in heavy truck and appliance manufacturing.

Amada Press System (Japan): The gold standard for high-speed precision in the electronics and small-parts sectors.

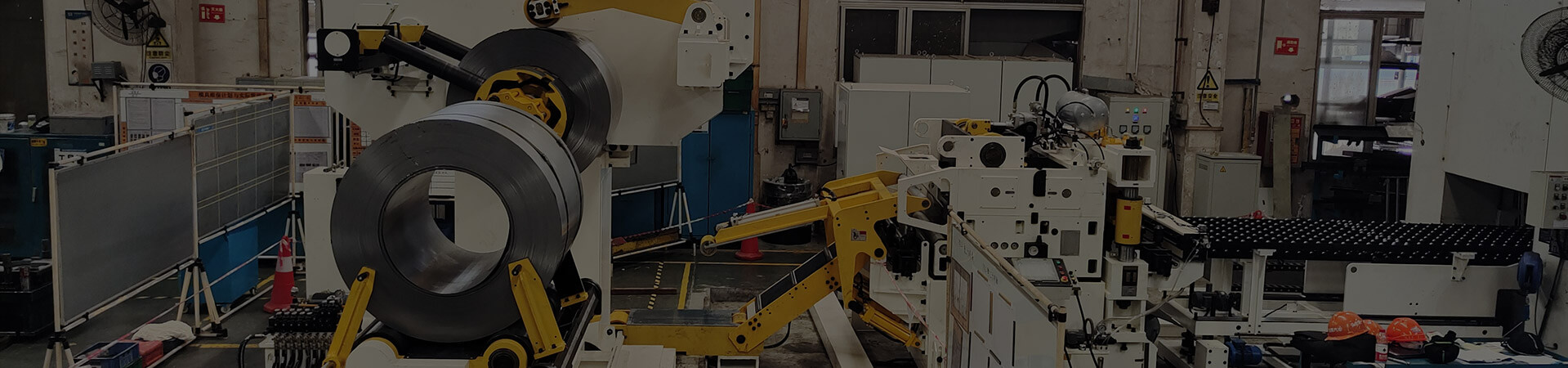

Spotlight: The SUNRUI MFL4-GF Series in Action

To understand why SUNRUI MACHINE is gaining such massive market share this year, we look at their flagship MFL4-GF Series High-Strength Compact 3-in-1 Feed Line.

Real-World Application: Automotive Structural Stamping

Imagine a factory floor producing car seat rails or brake pad foundations. These parts require material that is thick (up to 6.0mm) and incredibly strong (tensile strength up to 1500 MPa). Here is how the MFL4-GF handles the job:

Safety-First Loading: A hydraulic coil car loads a 15-ton coil. To prevent the dangerous "clock-spring" effect of high-tension steel, the Sunrui system utilizes a heavy-duty pneumatic pressing arm and a hydraulic "snubber" to hold the coil edge securely.

Hands-Free Threading: In 2025, labor safety is paramount. The MFL4-GF features an automated threading system that guides the leading edge of the steel into the rollers without the operator ever having to touch the sharp material.

The Power of Precision Straightening: Using GCr15 hardened rollers supported by a robust backup bearing system, the MFL4-GF exerts thousands of pounds of pressure to "break" the memory of the steel. The result is a strip of metal that is as flat as a tabletop, ensuring the stamping die never jams.

High-Speed Accuracy: Powered by Yaskawa or Siemens Servo drives, the line feeds the press at speeds of up to 22 meters per minute with a repeatable accuracy of ±0.15mm. This precision reduces scrap waste and significantly lowers the cost per part.

Why the MFL4-GF is the 2025 Choice for Smart Factories

Compact Footprint: As a "3-in-1" system, it integrates the decoiler, straightener, and feeder into one unit, saving up to 50% of floor space compared to traditional long-form lines. This space-saving advantage directly translates into a more flexible and efficient factory layout.

Durability: Built to withstand 24/7 high-vibration environments.

ROI & Value Proposition: It delivers European-level precision and safety features at a significantly more accessible price point, allowing for faster capital recovery. This high-performance-to-cost ratio enables manufacturers to upgrade their capability and improve their bottom line simultaneously.

Conclusion: A Verifiable Path to Higher Precision

As we look toward the future of automated manufacturing, the focus remains on safety, material capability, and space optimization. The SUNRUI MFL4-GF Series represents the pinnacle of these goals, proving that high-end automation is now more accessible and efficient than ever before.

For manufacturers ready to tackle the AHSS challenge, this system provides a clear, verifiable path to achieving higher precision, greater safety, and a faster return on investment. The next step is to assess how its capabilities align with your specific production demands.