Your 2025 Guide to Double Head Decoilers: Top Suppliers & Smart Tech Trends

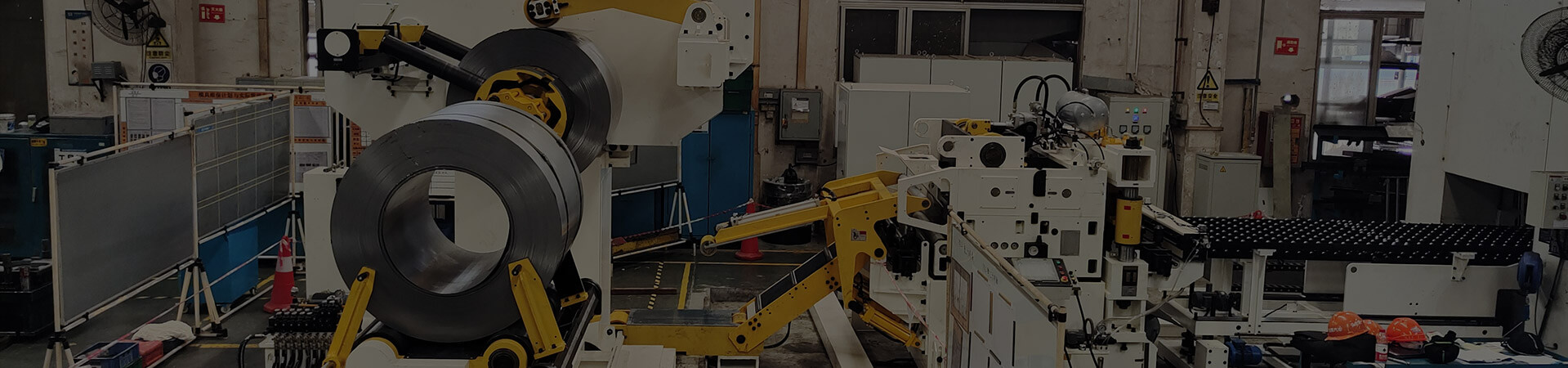

In today's high-speed, automated metal processing lines, downtime is profit evaporating. Every time a coil runs out and the entire production line grinds to a halt, you're not just losing minutes—you're losing money and competitive edge. This is where the double head decoiler transforms from a simple machine into a strategic asset.

Unlike single-head models, a dual-mandrel decoiler allows for continuous, uninterrupted production. While one head is actively feeding material, the other can be loaded with the next coil. The result? Near-zero downtime during coil changes and a dramatic boost in Overall Equipment Effectiveness (OEE).

But not all double head decoilers are created equal. As we move into 2025, the technology is evolving beyond mere mechanical reliability. The leaders are integrating predictive analytics, self-optimizing controls, and seamless data integration. Choosing the right supplier is now a decision that impacts your plant's productivity, flexibility, and intelligence for years to come.

This guide cuts through the noise. We’ve analyzed the market to bring you a definitive list of the most reliable suppliers for 2025 and the key technological trends that separate the future-proof from the obsolete.

The Global Leaders – Reliability Redefined

North American Powerhouses: Built for Heavy-Duty Performance

1. COE Press Equipment (USA)

A true titan in press feeding and coil handling, COE’s reputation is built on intelligent synchronization. Their double head decoilers are engineered not just as standalone units, but as the orchestrating brain of the entire press line. With advanced controls that communicate seamlessly with downstream levelers and presses, they ensure flawless material flow at blistering speeds, making them the

go-to choice for Tier-1 automotive and aerospace suppliers.

2. The Bradbury Group (USA)

Bradbury’s engineering philosophy centers on durability that eliminates downtime. Their double-mandrel designs, often used in demanding roll-forming applications, feature robust construction and ingenious safety mechanisms. The focus is on creating a machine that operators can trust for decades, with serviceability designed in from the start. If your environment is punishing and your schedule has no room for unscheduled maintenance, Bradbury is a prime contender.

3. Kent Corporation (USA)

Specializing in heavy-duty and custom solutions, Kent excels where standard machines fall short. If you’re processing ultra-high-strength steels, extra-wide coils, or exotic alloys, Kent’s engineers build decoilers with the power, frame strength, and precise tension control to handle it. They are problem-solvers for the most rigorous applications.

European Excellence: Precision Engineering

4. ARKU Maschinenbau (Germany)

ARKU represents the pinnacle of German precision and system integration. Their coil processing lines are masterpieces of synchronized engineering. For a double head decoiler, this means features like a “just-in-time” coil adjustment function that prepares the next coil’s diameter and width while the current one is running, enabling the fastest possible changeovers with absolute accuracy. It’s automation perfected.

Part 2: The Value Leaders – High Performance, Global Reach

5. Sacform / AGMline (Italy)

Praised for their robust hydraulic systems and innovative smart swivel bases, Sacform designs for speed. Their machines facilitate rapid coil changes with intuitive controls, making them a favorite for continuous, high-volume production of appliances and building materials. They strike an excellent balance between advanced European design and practical operational efficiency.

6. HENLI Machinery (China)

HENLI has built its reputation on delivering exceptional value without compromising on core quality. They focus on foundational robustness: using H-beam bases for stability, hardened main shafts for longevity, and reputable components from global brands like Schneider for electrical systems. For buyers seeking reliable performance with a keen eye on budget, HENLI is a top-tier international option.

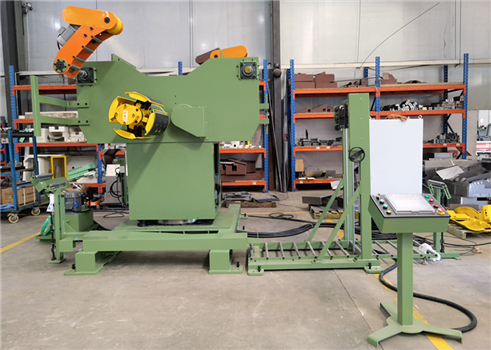

7. SUNRUI Machinery (China)

SUNRUI's mobile double-head decoilers stand out by solving real-world production challenges with robust, tailor-made solutions. Unlike competitors who design for ideal conditions, SUNRUI engineers for practicality—offering integrated setups such as decoilers paired with forklift-accessible coil upenders for facilities without overhead cranes. With a wide range of models covering speeds from 60 m/min to 300 m/min and capacities up to 6 tons per side, every system can be fully customized. Combined with one-touch loading, comprehensive safety interlocks, and dedicated after-sales support, SUNRUI doesn't just supply machines—it delivers production-ready workflows that boost flexibility, maximize output, and accelerate ROI by eliminating manual bottlenecks.

The 2025 Reliability Checklist – What “Smart & Durable” Really Means

In 2025, reliability is no longer just about heavy steel. It’s a combination of physical durability and digital resilience. Here’s what to demand from your next investment:

| Criteria | What it Meant in the Past | The 2025 Standard |

|---|---|---|

| Construction | Heavy-duty steel frame. | Smart Frame Design: Vibration-dampening structures, with embedded sensors to monitor stress and fatigue for predictive maintenance. |

| Components | Good quality parts. | Proven, Connected Components: Use of premium sub-supplier brands (e.g., Siemens, Bosch Rexroth) with IoT-ready interfaces for performance tracking. |

| Control & Precision | Basic PLC, manual tuning. | Adaptive Intelligence: AI-assisted tension control that learns from material variations, and auto-correction systems that communicate with the line’s digital twin. |

| Support & Uptime | Reactive phone support. | Proactive & Predictive Support: Remote diagnostics, guaranteed spare parts availability via digital inventory, and AR-assisted repair guides to minimize technician resolution time. |

| Integration | A machine that works alone. | A Networked Node: OPC UA compatibility, seamless data export for MES/ERP systems, and the ability to receive production schedules directly from the plant’s central system. |

The Bottom Line: The most reliable decoiler in 2025 is the one that not only rarely breaks down but also constantly provides the data to prevent breakdowns and seamlessly integrates into your wider smart factory ecosystem.

Making Your Choice: A Quick Decision Framework

Still unsure? Ask yourself these questions:

“Is top-tier, no-compromise performance my #1 goal, with budget as a secondary concern?”

→ Look to COE or ARKU. You're investing in the industry benchmark.

“I need a rugged, dependable workhorse for a tough North American plant environment.”

→ Bradbury and Kent are engineered for this exact scenario.

“I seek excellent performance and smart features with a strong focus on overall value and ROI.”

→ The international leaders Sacform and COTECH are compelling choices.

“My application is unique, or I need a complete, customized material handling solution.”

→ Engage with specialists or discuss custom options with SUNRUI.

The Future is Continuous

Investing in a double head decoiler in 2025 is no longer just a purchase—it’s a strategic upgrade to your production philosophy. You’re choosing a partner that will enable continuous flow, provide actionable intelligence, and adapt to the increasing demands of modern manufacturing.

By selecting a supplier from this list that aligns with both your technical needs and your plant’s digital roadmap, you’re not just buying a machine to change coils. You’re securing a foundation for uninterrupted growth and resilient, data-driven production for the decade ahead.

Ready to eliminate downtime? Start your journey by requesting detailed specifications and a virtual demo from the suppliers that match your profile. The future of your production line starts with the perfect first step.