Selection and Operation of Press Feeding Line

The selection and operation of a press feeding line are crucial for ensuring efficient and reliable operation in metal stamping and forming processes.

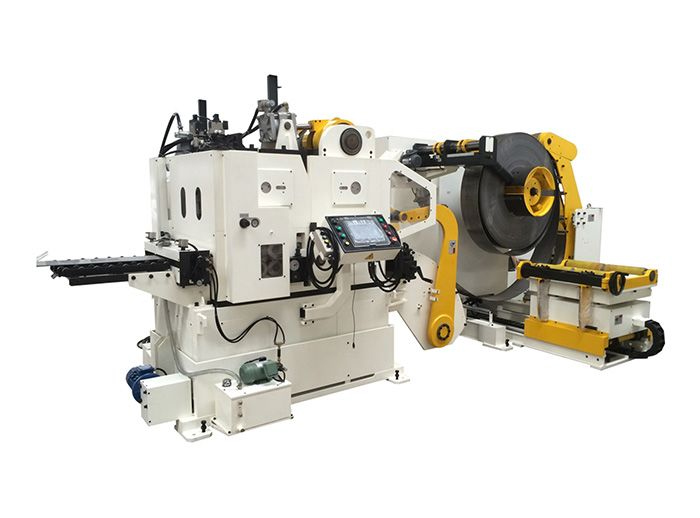

The selection and operation of a press feeding line are crucial for ensuring efficient and reliable operation in metal stamping and forming processes. A press feeding line consists of various components, such as decoilers, straighteners, and feeders, which work together to deliver the metal strip or coil to the press machine. In this guide, we will discuss the key considerations for selecting a press feeding line and provide insights into its operation.

Selecting a Press Feeding Line:

When selecting a press feeding line, several factors need to be considered to ensure optimal performance and compatibility with the specific application. Here are some important considerations:

Material Type and Thickness: Determine the type and thickness of the material to be processed. Different materials, such as steel, aluminum, or stainless steel, may require specific feeding line configurations and capabilities.

Coil Width and Weight: Consider the width and weight of the coils or metal strips to be processed. The feeding line should be capable of accommodating the desired coil dimensions and weight capacities.

Speed and Production Volume: Determine the required speed and production volume of the press line. This will help determine the appropriate feeding line capacity and capabilities to meet production requirements.

Automation and Integration: Assess the level of automation and integration required. Some feeding lines offer advanced automation features, such as programmable controls, servo-driven systems, and interface compatibility with press machines and production monitoring systems.

Feeding Accuracy and Precision: Consider the required feeding accuracy and precision for the specific application. Higher accuracy may require features like servo-driven feeders or precision straighteners to ensure consistent material feeding.

Coil Changeover: Evaluate the frequency and ease of coil changeovers. Quick and efficient coil changeover mechanisms can minimize downtime and improve productivity.

Operator Safety and Ease of Use: Consider the safety features and ergonomic design of the feeding line. Features such as safety guards, emergency stops, and intuitive controls contribute to the overall safety and ease of operation.

Operation of a Press Feeding Line:

Once a press feeding line is selected and installed, proper operation is essential for optimal performance. Here are some key aspects of operating a press feeding line:

Setup and Calibration: Ensure the feeding line is properly set up and calibrated according to the material specifications and process requirements. This includes adjusting the straightener settings, feed roll pressure, and feed length.

Material Handling: Proper material handling is crucial to prevent damage or misfeeds. Make sure the coils or metal strips are loaded onto the decoiler and straightener correctly, and that they feed smoothly into the press.

Feeding Line Controls: Familiarize yourself with the controls and operating parameters of the feeding line. This includes understanding the control panel, setting the feeding speed, adjusting the feed length, and monitoring feeding accuracy.

Regular Maintenance: Implement a regular maintenance schedule to ensure the feeding line operates smoothly. This includes inspecting and lubricating moving parts, checking and adjusting tension settings, and replacing worn-out components as needed.

Troubleshooting: Develop troubleshooting skills to identify and resolve common issues that may arise during operation. This may include problems such as misfeeds, material jams, or inconsistencies in feeding accuracy.

Operator Training: Ensure that operators receive proper training on the operation and safety procedures of the feeding line. This includes understanding the functionality of each component, troubleshooting techniques, and safety protocols.

Continuous Monitoring and Optimization: Continuously monitor the performance of the feeding line and make adjustments as necessary to optimize feeding accuracy, minimize downtime, and maximize productivity.

By following these guidelines for selecting and operating a press feeding line, manufacturers can enhance the efficiency and reliability of their metal stamping and forming processes. It is crucial to consult with suppliers or industry professionals to ensure the chosen feeding line meets the specific requirements of the application and to receive guidance on proper installation and operation procedures.

For more information, please contact us. We will provide professional answers.