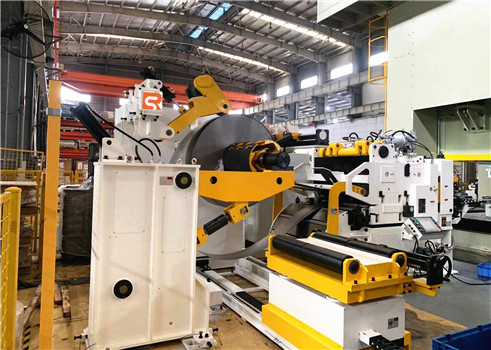

SUNRUI Coil Feed Line --- Decoiler Straightener Feeder 3 in 1 for Auto Parts

Introduce the key components of a coil feed line system and analyze their importance and the impact of efficient operation on coil processing.

The coil feed line system is an extensively used automation equipment in the manufacturing industry, which is used to supply coil materials in specified sizes and lengths for the next process. The key components of this system include a decoiler, a straightener feeder, and a hydraulic shear. This report will provide a detailed introduction to the functions, roles, and importance of these components.II. Key components of the coil feed line.

A. Decoiler

Function and role

The decoiler is the first process in the coil feed line system, mainly used to unwind the coil material and control the feeding speed to supply the uncoiled coil material to the next process, ensuring continuous material supply.

Coil control and unwinding

The decoiler ensures stable material supply by controlling the feeding speed and tension of the coil. It can also rewind the processed coil for storage and transportation.

B. Straightener feeder

Function and role

The straightener feeder is mainly used to stretch and straighten the coil material to meet the requirements of the processing process. It can eliminate the bending and twisting of the coil material, ensuring its flatness and stability.

Stretching and straightening of coil material

The straightener feeder stretches and straightens the coil material through a series of rollers and tension devices. This ensures the surface flatness of the coil material and avoids problems in subsequent processing.Accurate supply to the next process

The straightener feeder can supplyened coil material accurately to the next process, ensuring processing accuracy and consistency.

C. Hydraulic shear

Function and role

The hydraulic shear is mainly used to cut the coil material to adjust its size and length. It can achieve fast and precise cutting operations, ensuring that the coil material meets the processing requirements.

Cutting of coil material

The hydraulic shear provides strong cutting force through the hydraulic system, capable of cutting the coil material to the required length and size. Its high cutting speed and precision can meet the requirements of different processing techniques.

Adjustment of size and length

The hydraulic shear can also adjust the size and length of the coil material according to actual needs. This makes the production process more flexible and adaptable to different coil processing specifications.

Based on the detailed introduction of the key components of the coil feed line, we can see the importance of these components in the coil feed line system. In the next section, we will further discuss the importance of their efficient operation on coil processing and the significance of optimizing equipment configuration and operating procedures.

Importance of key components of coil feed line

A. Importance of Decoiler:

The decoiler is one of the key components in the coil feed line system, with its function and role primarily focused on controlling and winding the coil. It can unwind the coil from the decoiler and supply it to the next process at the required speed and tension. Therefore, the proper operation of the decoiler is crucial for the entire coil processing process. If the decoiler malfunctions or operates unstably, it will result in unstable material supply, affecting subsequent processes. Therefore, ensuring the stability and reliability of the decoiler is one of the key factors in ensuring the quality of coil processing.

B. Importance of Straightener feeder:

The straightener feeder is another key component in the coil feed line system, with its function and role primarily focused on stretching, straightening, and accurately supplying the coil material to the next process. The proper operation of the straightener feeder not only ensures the quality and accuracy of the coil material but also improves production efficiency and reduces the difficulty of manual operation. Therefore, the stability and accuracy of the straightener feeder are crucial for the quality and efficiency of coil processing.

C. Importance of Hydraulic shear:

The hydraulic shear is the third key component in the coil feed line system, with its function and role primarily focused on cutting the coil material and adjusting its size and length. In the coil processing process, it is often necessary to cut and adjust the coil according to specific product requirements. The hydraulic shear provides stable and precise cutting functions, ensuring that the coil material meets the size and length requirements. Therefore, the proper operation of the hydraulic and consistency of coil processing.

Importance of efficient operation of key components on coil processing:

A. Significance of optimizing equipment configuration and operating procedures:

Efficient operation of the key components can be achieved by optimizing equipment configuration and operating procedures. For example, the layout of the key components in the coil feed line system can be properly arranged to ensure smooth and efficient transfer and collaboration between them. Similarly, the operating procedures need to be planned and adjusted properly to ensure the connection and coordination between the key components. By optimizing equipment configuration and operating procedures, the efficiency and stability of the coil processing can be maximized.

B. Impact on improving production efficiency and quality:

The efficient operation of the key components has an important impact on improving the production efficiency and quality of coil processing. If the key components operate unstably or have malfunctions, it will result in unstable material supply or inaccurate dimensions, affecting the product quality. On the other hand, when the key components operate efficiently, it ensures stable material supply and accurate dimensions of the coil material, thereby improving the consistency and quality of the product. Therefore, the efficient operation of the key components is of great significance in improving the production efficiency and quality of coil processing.

In conclusion, the decoiler, straightener feeder, and hydraulic shear are crucial components of the coil feed line system, and their importance not be overlooked. Their efficient operation has a significant impact on ensuring the quality and production efficiency of coil processing. Therefore, it is necessary to strengthen the management and maintenance of these key components and optimize equipment configuration and operating procedures to improve their efficiency and stability. Only by ensuring the efficient operation of these key components can high-quality and efficient coil processing be achieved.

Summary of the coil feed line

A. Summary of the coil feed line:

The coil feed line is a crucial production system used for coil feeding and processing. Through a detailed introduction to the functions and roles of key components such as the decoiler, straightener feeder, and hydraulic shear, we can understand the importance and necessity of these components in the coil processing process.

B. Significance of optimizing equipment configuration and operating procedures:

Optimizing equipment configuration and operating procedures have a significant impact on the efficiency and quality of coil processing. By properly configuring equipment, such as linking the decoiler, straightener feeder, and hydraulic shear, continuous feeding and processing of the coil can be achieved, greatly improving production efficiency. At the same time, optimizing operating procedures, such as standardizing equipment operation and adjustment, can reduce the possibility of operational errors and malfunctions, improving production stability and reliability.

C. Importance of improving production efficiency and quality:

Improving production efficiency and quality is a key goal in the coil processing process. By using efficient equipment and proper operating procedures, the accuracy of coil dimensions can be ensured, guaranteeing the quality of the products. Moreover, optimizing equipment configuration and operating procedures can reduce waste and losses in the coil processing process, improving production economy and sustainability.

In conclusion, the coil feed line is an important production system, and by optimizing equipment configuration and operating procedures, production efficiency and quality can be improved, resulting in efficient coil processing. Therefore, it is essential to recognize the roles and importance of key components and continuously strive to improve and optimize the coil processing process to meet market demands and enhance competitiveness.