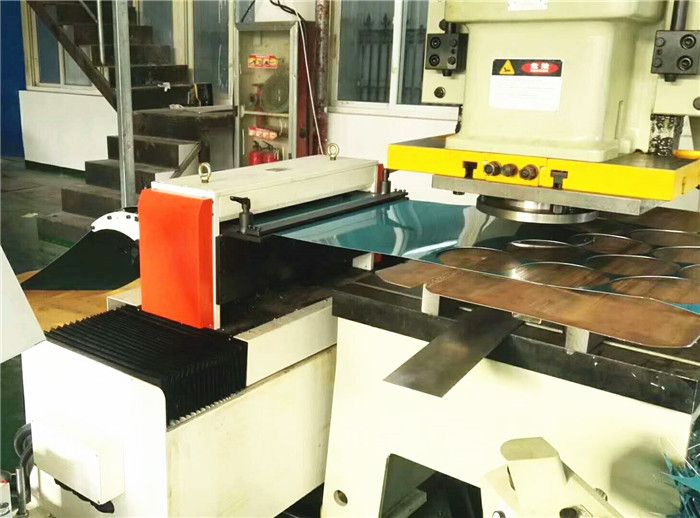

Circle Blanking Coil Processing Line

Applicable material

Material Type: Cold rolled plate, Hot rolled pickling plate, High strength cold rolled plate, Galvanized plate, High strength hot rolled plate etc.

Material Thickness: 0.3-2.0mm

Coil Width: 200-1300mm

Coil inner diameter: Φ508mm

Coil outer diameter: Φ1200mm

Circle Blanking Coil Processing Line Is Popular In Household Electrical Appliances Industry

Circle Blanking Coil Processing Line offer dramatic productivity advantages in stagger feeding.

Stagger feeding parts in a Zig-Zag Press Feed System can boost productivity and provide up to 22 % material savings.

Zig Zag or Stagger Servofeed is driven by an Yaskawa Servomotor through a precision gear train while the lateral travel of the feed and material is powered by a combination Yaskawa Servomotor and linear ball screw.

This Circle Blanking Coil Processing Line with high Efficiency, saving material utilization rate of washer drawing function, can be a variety of coil material by uncoiling, straightening, punching, shift around circular plate is the efficient processing of different specifications of pipeline materials under the sheet metal processing wafer. We also cam add the auto stack device, can be collected the circle into wafer stacking.

Circle Blanking Coil Processing Line Configuration

First configuration for Circle Blanking Coil Processing

Coil line configuration is as below

1. Decoiler

2. Zigzag NC servo Feeder Machine

3. Stamping Press

4. Conveyor Belt

Second configuration for Circle Blanking Coil Processing

Coil line configuration is as below:

1. Combined Decoiler Straightener 2 in 1

2. Zigzag NC servo Feeder Machine

3. Stamping Press

4. Conveyor Belt

Third configuration for Circle Blanking Coil Processing

Coil line configuration is as below:

1. Compact zigzag coil feed line

2. Stamping Press

3. Conveyor Belt

Video For Circle Blanking Coil Processing